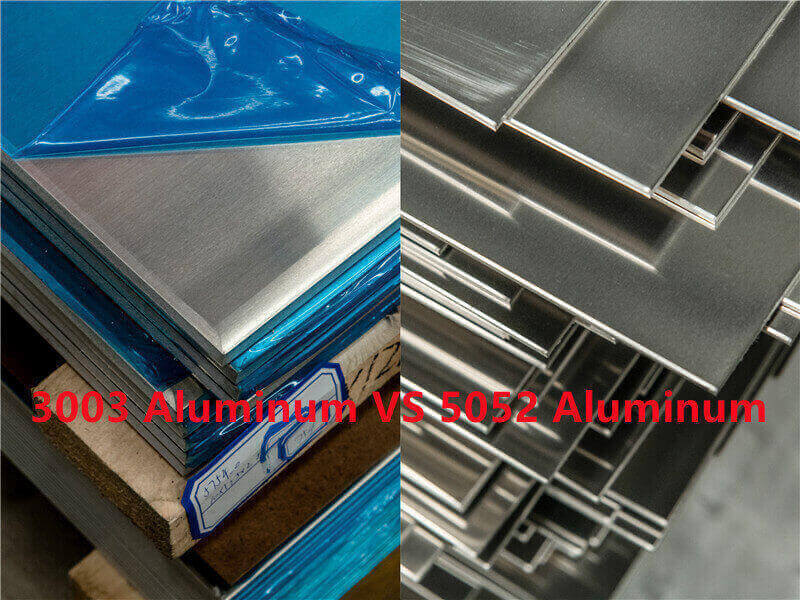

What is the difference between 3003 and 5052 aluminum? Today, let’s learn the 3003 aluminum vs 5052 aluminum!

3003 aluminum alloy and 5052 aluminum alloy are two kinds of aluminum alloys that are widely used in business. They belong to different series of aluminum alloys. 3003 aluminum belongs to the Mn-Al alloy series. 5052 aluminum belongs to the Mg-Al alloy series.

The aluminum content of 3003 aluminum and 5052 aluminum is as high as 96%. But, other alloying elements are different, so their properties and uses are also significantly different. As a Chinese aluminum alloy manufacturer, we will use our professional knowledge to clarify the difference between aluminum 3003 vs 5052 from the following aspects.

3003 aluminum vs 5052 aluminum

- Chemical Composition

- Features and Application

- various properties

- Price

3003 vs 5052 aluminum Chemical Composition

| Al | Cr | Cu | Fe | Mg | Mn | Si | Zn | Residuals | |

| 3003 | Remainder | – | 0.05-2.0 | 0.7 | – | 1.0-1.5 | 0.60 | 0.10 | 0 |

| 5052 | Remainder | 0.15~0.35 | ≤0.10 | ≤0.40 | 2.2~2.8 | ≤0.10 | ≤0.25 | ≤0.10 | 0.15 |

It is obvious from the above table that there is a clear difference in the chemical composition of 3003 aluminum and 5052 aluminum. Besides aluminum, the manganese content of 3003 aluminum alloy is the highest. The Mg content of 5052 aluminum is the highest.

The difference in these alloying elements makes their properties distinct.

3003 aluminum vs 5052 aluminum Features and Applications

3003 aluminum is the most widely used common alloy. Its strength is medium. It has very good machinability. And 3003 aluminum alloy can be welded and brazed by all methods. The strength of 5052 aluminum is higher than that of 3003 aluminum.

5052 aluminum has the highest strength in non-heat-treated aluminum sheets.

The Cu content of 5052 aluminum is very small, so its corrosion resistance is better than that of 3003 aluminum.

In terms of mechanical properties, the tensile strength and yield strength of 5052 aluminum are significantly higher than those of 3003 aluminum. Therefore, the performance of 5052 aluminum is better than that of 3003 aluminum plate.

On the usage, 3003 aluminum sheet is very suitable for medium strength English. Such as plumbing, fuel tanks, chemical equipment, spinning, cookware, food containers. chemical equipment, pressure vessels, general sheet metal fabrication, hardware, tanks and cabinets. And 5052 aluminum is more suitable for higher strength sheet metal fabrication. Marine, tanks, automobiles, food service and medical equipment.

Because 5052 aluminum has better corrosion resistance than 3003 aluminum. It is also widely used in marine and aquatic facilities. Similarly, 6061 aluminum is also very suitable for high-strength sheet metal fabrication and marine and aquatic facilities because of its high strength and excellent corrosion resistance.

5052 aluminum vs 3003 Various properties

aluminum alloy 3003 vs 5052 alloy Mechanical Properties

| 3003 | 5052 | |

| Elastic Modulus /GPa | 70 | 68 |

| Elongation at Break/% | 1.1-28 | 1.1-22 |

| Fatigue Strength/MPa | 39-90 | 66-140 |

| Poisson’s Ratio | 0.33 | 0.33 |

| Shear Modulus/GPa | 26 | 26 |

| Shear Strength/MPa | 68-130 | 120-180 |

| Tensile Strength/MPa | 110-240 | 190-320 |

| Tensile Strength: Yield /MPa | 40-210 | 75-280 |

3003 aluminum vs 5052 aluminum Thermal Properties

| Item | 3003 | 5052 |

| Latent Heat of Fusion, J/g | 400 | 400 |

| Maximum Temperature: Mechanical, °C | 180 | 190 |

| Melting Completion (Liquidus), °C | 650 | 650 |

| Melting Onset (Solidus), °C | 640 | 610 |

| Specific Heat Capacity, J/kg-K | 900 | 900 |

| Thermal Conductivity, W/m-K | 180 | 140 |

| Thermal Expansion, µm/m-K | 23 | 24 |

3003 aluminum vs 5052 aluminum Electrical Properties

| 3003 | 5052 | |

| Electrical Conductivity: Equal Volume, % IACS | 44 | 35 |

| Electrical Conductivity: Equal Weight (Specific), % IACS | 140 | 120 |

Other properties

| 3003 | 5052 | |

| Base Metal Price, % relative | 9.5 | 9.5 |

| Calomel Potential, mV | -740 | -760 |

| Density, g/cm3 | 2.8 | 2.7 |

| Embodied Carbon, kg CO2/kg material | 8.1 | 8.6 |

| Embodied Energy, MJ/kg | 150 | 150 |

| Embodied Water, L/kg | 1180 | 1190 |

3003 aluminum vs 5052 aluminum Common Calculations

| 3003 | 5052 | |

| Resilience: Ultimate (Unit Rupture Work), MJ/m3 | 0.95-63 | 1.7-69 |

| Resilience: Unit (Modulus of Resilience), kJ/m3 | 11-300 | 41-590 |

| Stiffness to Weight: Axial, points | 14 | 14 |

| Stiffness to Weight: Bending, points | 50 | 50 |

| Strength to Weight: Axial, points | 11-24 | 19-33 |

| Strength to Weight: Bending, points | 18-30 | 27-39 |

| Thermal Diffusivity, mm2/s | 71 | 57 |

| Thermal Shock Resistance, points | 4.7-10 | 8.3-14 |

Through data comparison, we can see that the mechanical properties of 5052 aluminum are significantly better than 3003 aluminum. For example fatigue strength, shear strength, tensile strength, tensile strength.

5052 vs 3003 aluminum Price

The price of 3003 aluminum alloy and 5052 aluminum alloy is also a matter of concern to everyone. The price of 3003 aluminum plate is slightly higher than that of 1000 series aluminum plate. The price of 5052 aluminum plates is significantly higher than that of 3003 aluminum plates.

Our products

| Alloy | 3003 Aluminum、5052 Aluminum、other aluminum |

| Shape | Aluminum sheet、Aluminum coil、Aluminum foil |

| Temper | O,H12,H14,H18,H22,H24,H26,H28,H112, |

| Thickness | 0.1mm-550mm |

| Width | 900mm-2700mm |

| Length | 500mm-15000mm |

| We can also customize the size according to customer’s request |

We are a professional manufacturer of aluminum alloy products, if you need aluminum alloy related products, welcome to consult. We will use our professional knowledge to provide you with suitable products.

FAQ

Better aluminum for bending: aluminum 3003 vs 5052?

3003, 5052, 6061 aluminum are 3 kinds of aluminum alloys suitable for bending. The elongation of 3003 aluminum alloy is 25%, which is the most suitable aluminum alloy for bending, the elongation of 5052 aluminum is 20%, and the elongation of 6061 aluminum is 18%.

In terms of bendability, 3003 aluminum is the most suitable aluminum alloy for bending, 5052 aluminum is not as good as 3003 aluminum, and 6061 aluminum is not as good as 5052 aluminum.

Is aluminum 5052 vs 3003 better for anodized?

5052 aluminum is more suitable for anodizing than 3003 aluminum。

The color of 3003 aluminum alloy is uneven after anodizing, so 3003 aluminum alloy is generally not anodized.