Description:

1Cr17Ni2 series is a kind of martensitic stainless steel with good combination of strength and toughness. It has good corrosion resistance to oxidizing acids, most organic acids and aqueous solutions of organic salts.

Worldwide equivalents

| China | EU | USA | Germany | Poland | Russia |

| GB | EN | – | DIN,WNr | PN | GOST |

| 1Cr17Ni2/ML1Cr17Ni2 | X17CrNi16-2 (1.4057) | 431 | X17CrNi16-2 | 2H17N2 | 14KH17N2/20KH17N2 |

1Cr17Ni2 Steel Material Chemical Composition

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) |

| 0.11-0.17 | ≦0.8 | ≦0.8 | ≦0.035 | ≦0.03 | 16.0-18.0 | 1.5-2.5 |

1Cr17Ni2 Steel Mechanical Properties

| Tensile strength | 321~495 | σb/MPa |

| Yield Strength | 183 | σ 0.2 ≥/MPa |

| Elongation | 98 | δ5≥(%) |

| HBS | 802~096 | – |

| HRC | 30 | – |

1Cr17Ni2 Steel Physical Properties

| Thermal expansion | 45-25 | e-6/K |

| Thermal conductivity | 04-31 | W/m.K |

| Specific heat | 450-460 | J/kg.K |

| Melting temperature | 7053-0587 | ℃ |

| Density | 7596-5729 | kg/m3 |

| Resistivity | 0.50-0.60 | Ohm.mm2/m |

Heating processing

Heat treatment

When the temperature of cold charging furnace is ≤ 800 ℃ (the temperature of hot charging furnace is unlimited), the starting temperature is 1100 ~ 1150 ℃, the ending temperature is > 850 ℃, and the temperature is > 50 ℃, it is cooled slowly in the sand.

Low temperature annealing

Annealing temperature 670 ℃, furnace cooling.

High temperature annealing

Annealing temperature 850 ~ 870 ℃, oil cooling or air cooling, hardness ≤ 250hbw.

Quenching and tempering

1) Quenching temperature 950℃ ~ 1050℃, oil cooling, tempering temperature 275 ~ 350℃, air cooling, tensile strength ≥ 1100mpa, elongation ≥ 10%, impact toughness ≥ 50J / cm2, hardness ≤ 285HBW.

2) Quenching temperature 950 ~ 1050 ℃, oil quenching, tempering temperature 280 ~ 350℃, air cooling, tensile strength 1100 ~ 1730mpa, elongation 10% ~ 22%, impact toughness 25 ~ 50J / cm2, hardness 187 ~ 286HBW.

Features and application scope

1Cr17Ni2 steel is a martensitic stainless and acid-resistant steel with high strength and hardness.

1Cr17Ni2 steel has good corrosion resistance to partially oxidizing acids and organic acid aqueous solution at a certain temperature. It is suitable for manufacturing plastic molds and transparent plastic product molds under the action of corrosive media. However, the steel has poor welding performance and is easy to produce cracks. It is not suitable to weld when manufacturing molds.

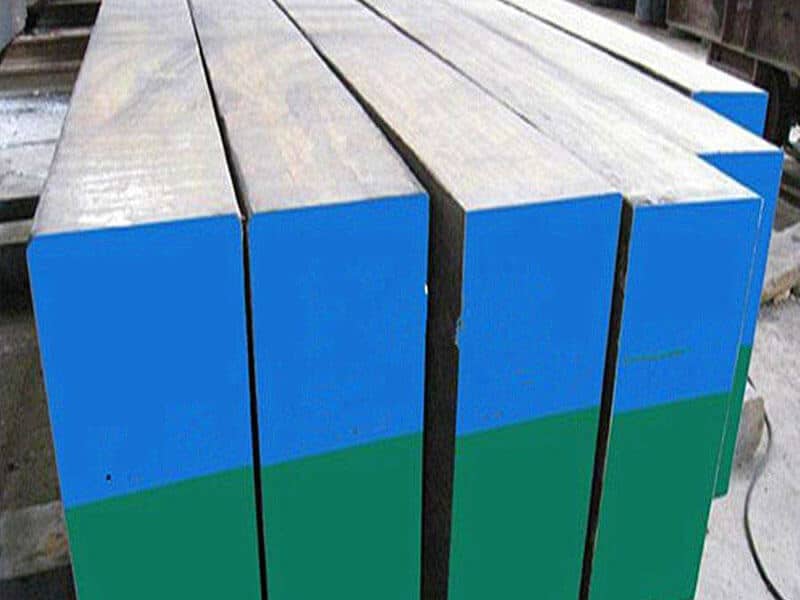

1Cr17Ni2 Steel Supply

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, Hot rolling, cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | 8-1200mm*L | Forging, Hot rolling, cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |