Description

30CrMnSiNi2A alloy structural steel. High strength, good ductility and toughness can be obtained after heat treatment. Good fatigue resistance and fracture toughness. Low fatigue cracks growth rate.

Chemical Composition

| C | Si | Mn | S | P | Cr | Ni | |

| % | 0.27-0.34 | 0.90-1.20 | 1.00-1.30 | 0.020 MAX | 0.020 MAX | 0.90-1.20 | 1.40-1.80 |

Mechanical Properties

Tensile strength σb (MPa): 1) 1767; 2) 1627

Elongation δ5 (%): 1) 12; 2) 13

Reduction of ψ (%): 50

Impact toughness αku (J / cm2): 1) 79; 2) 90

Sample size: bar

Physical properties

The critical temperature of 30CrMnSiNi2A Steel

| Critical piont | Ac1 | Ac3 | Ms |

| Temperature/℃ | 705 705 | 800 815 | 321 314 |

Elastic modulus of 30CrMnSiNi2A Steel

| Temperature/℃ | 20 | 100 | 200 | 250 |

| Elastic modulus E/MPa | 211000 | 208000 | 204000 | 202000 |

Linear Expansion Coefficient of 30CrMnSiNi2A Steel:

| Temperature/℃ | 20 | 17~100 | 17~200 | 17~300 | 17~400 | 17~500 | 17~600 | 17~700 | 17~800 | 17~900 |

| Linear Expansion Coefficient /C | 10.55 | 11.37 | 11.67 | 12.68 | 12.9 | 13.55 | 13.8 | 13.9 | 11.15 | 12.1 |

Thermal conductivity of 30CrMnSiNi2A Steel:

| Temperature/℃ | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| Thermal conductivity λ/W·(m·K) | 25.7 | 28.0 | 29.3 | 29.9 | 29.3 | 28.2 | 27.0 | 25.7 | 24.0 | 22.3 |

Mass constant pressure heat capacity of 30CrMnSiNi2A Steel:

| Temperature/℃ | 20 | 100 | 200 | 300 | 400 | 500 | 600 |

| Mass constant pressure heat capacitycp/J·(kg·K) | 472.3 | 526.6 | 518.0 | 639.5 | 698.0 | 752.4 | 831.8 |

Heat treatment

1) 890 ~ 900 ℃ oil quenching, 200 ~ 300 ℃ tempering, air-cooled;

2) 890 ~ 900 ℃ heated, quenched into 210 ~ 280 ℃ nitrate bath isothermal 1h, air-cooled, and then at 200 ~ 300 ℃ tempering, air-cooled.

Features

High hardenability. Machinability and weldability are good. But sensitive to notch and hydrogen embrittlement (including environmental hydrogen embrittlement).

30CrMnSiNi2A is suitable for important stress-bearing structural components. Such as high-strength connectors and shaft parts.

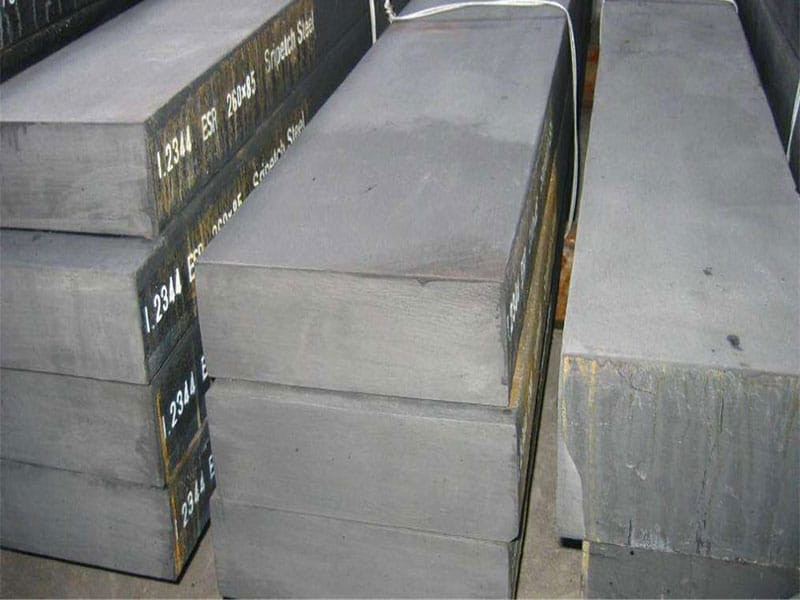

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |