Description

5Cr4W5Mo2V steel is a new type of hot work die steel. The steel has a high hot hardness, high-temperature strength and high wear resistance. It can be used for general heat treatment or chemical heat treatment. It can replace 3Cr2W8V steel to manufacture some hot extrusion dies. It is also used in the manufacture of precision forging dies, hot stamping dies, punch dies with high service life.

5Cr4W5Mo2V Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | Mo | V | W | Cu |

| 0.40~0.50 | ≤0.40 | ≤0.40 | P≤0.030 | P≤0.030 | 3.40~4.40 | ≤0.20 | 1.50~2.10 | 0.70~1.10 | 4.50~5.30 | ≤0.30 |

5Cr4W5Mo2V Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition |

| 627(≥) | 298(≥) | 11 | 21 | 13 | Solution and Aging, Annealing, Ausaging, Q+T |

5Cr4W5Mo2V Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 124(≥) | 515(≥) | 13 | 13 | 23 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 147 | 639 | 145 | Solution and Aging,Annealing, Ausaging,Q+T | 443 |

5Cr4W5Mo2V Heat Treatment

Thermal processing

The heating temperature is 1170-1190°C, the starting temperature is 1120-1150°C. The end temperature is ≥850°C. After hot working, it should be cooled quickly in the range of 600-850°C to avoid the precipitation of carbides along the grain boundary. Slow cooling at ≤600°C.

Spheroidizing Annealing

Annealing temperature (870±10)℃, hold for 3h. Cool down to (730±10)℃, hold for 4h, furnace cool to ≤500℃, and air-cool the furnace. The hardness after spheroidizing annealing temperature is 200HBW, and the spheroidizing structure is grade 2.

Quenching, tempering

Preheating temperature 500℃, holding for 2h. The second preheating temperature is 860℃, holding for 2h. Raised to quenching temperature (1140±10)℃, holding for 30min. Oil cooling to 180-200℃, oil outlet air cooling, 600-610 ℃ × 2h air cooling and tempering twice.

Application

1. It is suitable for making small precision forging molds, flat forging molds, stamping mold punches. Hot extrusion punches, trimming molds, roll forging molds.

2. Especially suitable for copper alloy extrusion mold, warm forging mold. Hot extrusion punch mold with small impact toughness load

3. Trimming molds, gear precision forging molds, bearing ring extrusion punches. Stainless steel tableware rolling molds are much longer than the original H13 steel and 3Cr2W8V mold steel.

4. Used to make hot extrusion mold to replace 3Cr2W8V steel

5. It is suitable for making hot work mold with high-temperature strength and wear resistance. It can replace 3Cr2W8V steel. The service life of the mold can be increased by 2-4 times.

6. It is suitable for making 600-650 ℃ precision forging molds. Hot roll molds, hot punches, small and medium-sized machine forging insert molds, etc.

7. Make gear precision forging mold. The service life is more than double that of the 4Cr5MoV1Si steel mold.

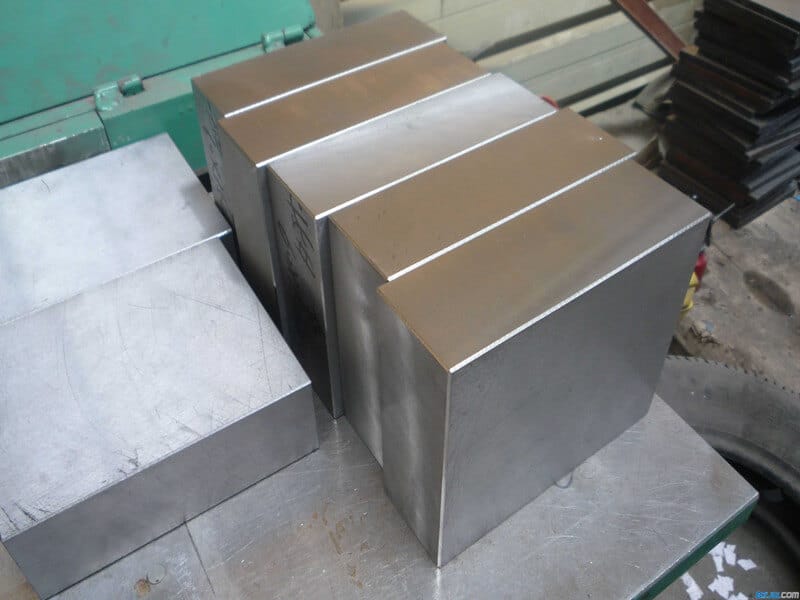

5Cr4W5Mo2V products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, Hot Rolling,Cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, Hot rolling, Cold rolling, Cast | Black, Rough Turning, Shot Blasting |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes,Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |