Description

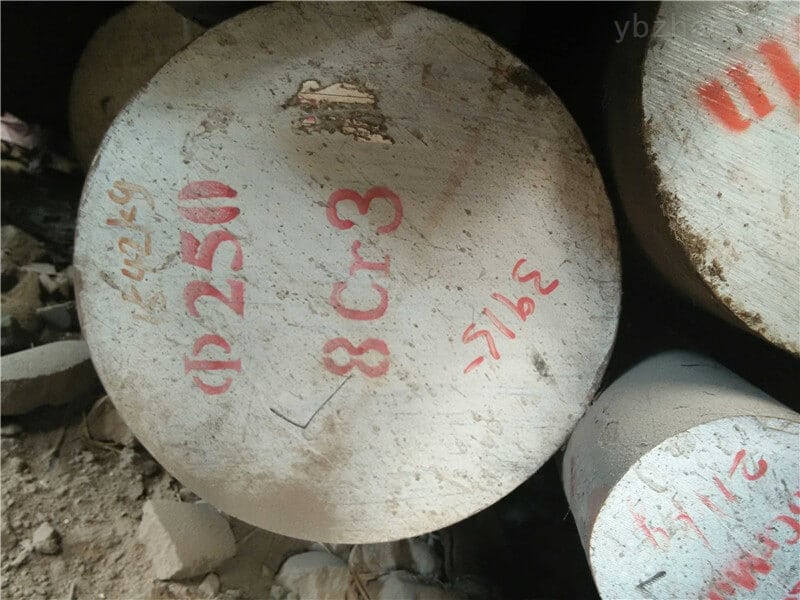

8Cr3 steel is formed by adding a certain amount of chromium (3.20%~3.80%) to carbon tool T8. Due to the presence of chromium, this steel has good hardenability and certain room temperature and high-temperature strength. Moreover, fine, uniformly distributed carbides are formed. This steel is usually used in the manufacture of hot blanking dies, hot upsetting dies, and hot bending molds.

8Cr3 Steel Material Chemical Composition

| C | Si | Mn | Cr | P | S |

| 0.75~0.85 | ≤0.40 | ≤0.40 | 3.20~3.80 | ≤0.03 | ≤0.03 |

8Cr3 Steel Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 192(≥) | 575(≥) | 12 | 44 | 12 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 241 |

C8Cr3 Steel Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Modulus of elasticity kN/mm2 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Thermal conductivity W/mK | Electric resistance µΩ·cm |

| 969(≥) | 111(≥) | 42 | 24 | 222 |

| 965 | 718 | 746 | 13 | Solution and Aging,Annealing,Ausaging,Q+T,etc |

Heat Treatment

Annealing:

Heating and heat preservation at 790 ~ 810 ℃ and cooling with the furnace to air cooling below 500;

Quenching:

850 ~ 880 degrees. Hardness: ≥HRC55

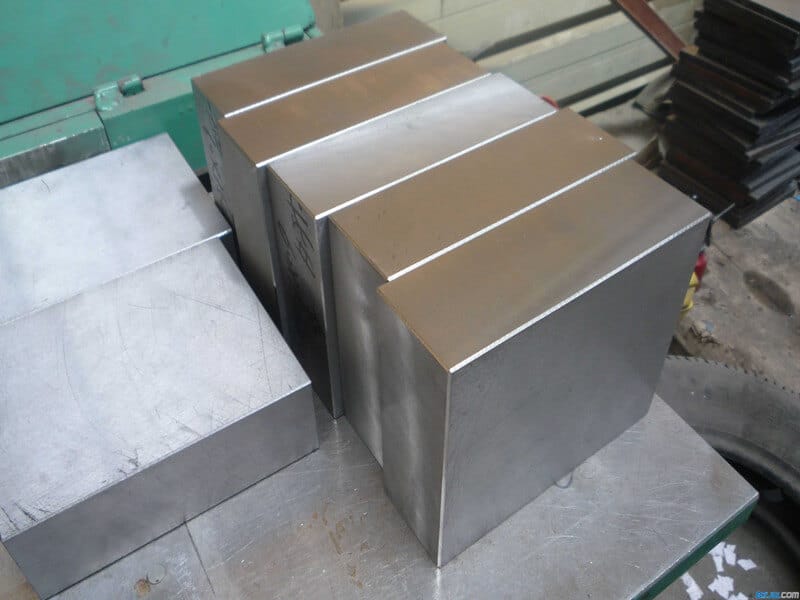

Cr12MoV products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |