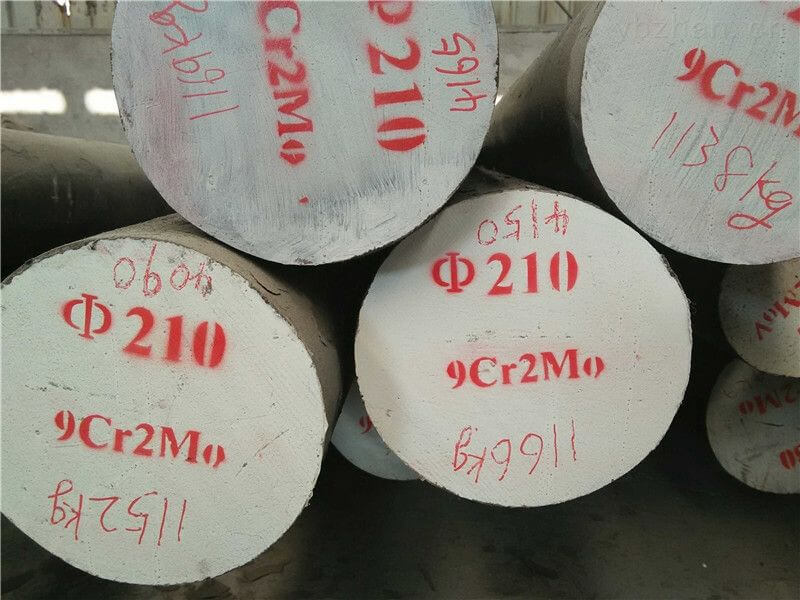

Description

9Cr2Mo material is a typical Cr2 series cold roll steel. It is used to manufacture rolls, pressing rolls and cold dies for cold rolling.

9Cr2Mo Worldwide Equivalents

| country / region | China | EU | Germany | Japan | France | England |

| Standard | GB | EN | DIN,WNr | JIS | AFNOR | BS |

| Grade | 9Cr2Mo | 90Cr3/1.2056 | – | – | BL3 | |

| country / region | Poland | Czechia | Austria | Russia | Inter | |

| Standard | PN | CSN | ONORM | r0CT | ISO | |

| Grade | – | – | – | 9X1 | – |

9Cr2Mo Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Mo |

| 0.85-0.95 | 0.25-0.45 | 0.20-0.35 | ≤0.025 | ≤0.025 | 1.70-2.10 | 0.20-0.40 |

9Cr2Mo Mechanical Properties

Annealing hardness HBW: ≤ 229

Rockwell hardness HRC: ≥ 64

Heat treatment process

1. Spheroidizing annealing. 790~810℃ heating, 650~670℃ isothermal, ≤500℃ air cooling;

2. Quenching. Heating temperature = 880~900℃, quenching and cooling. According to different workpiece structures and different requirements, cooling media. Such as water, PAG quenching fluid, and oil can be used.

3. Critical point temperature. Ac1 =740°C, Ar1 =700°C, Accm:850°C

4. The cold-pressed blank is generally softened. (820±10)°c ×3 ~4h, with a cooling rate of ≤15°C/h, slowly cool to ≤650°C with the furnace, and air-cooled.

5. Isothermal spheroidization and softening of cold-pressed blanks. (820±10) °C ×3 ~4h, (720 ±10) °C ×6 ~8h, and then slowly cooled to ≤600 °C with the furnace, and air-cooled. The hardness before treatment is ≤217HBW, and the hardness after treatment is ≥170HBW.

6. Normalizing. Normalizing temperature 900 ~ 920°C, hardness 302-388HBW.

7. Batch isothermal spheroidizing annealing. 790 ~810°C ×2 ~3h, furnace cooling, 7O0 -720°C ×3 ~4h, hardness≤217HBW, pearlite structure grade 2-5, mesh carbide grade≤2 grade

8. Quenching and tempering

- 1) Quenching temperature 830 – 850°C, Hardness 62~65HRC. Tempering temperature 130~150°C, hardness 62~65HRC.

- 2) Quenching temperature 840~860°C, hardness 61~63HRC. Tempering temperature 150~170°C, hardness 60~62HRC.

9Cr2Mo features and Applications

Rolls, press rolls and cold dies for cold rolling.