Description

9CrWMn steel is a typical alloy Cold Mold Steel steel with high performance on cold work mechanical processes.

9CRWMN steel with high abrasion resistance, micro deformation of cold work die steel. The wind hard tool steel, carbon content as high as 0.95%. The heat treatment hardness can reach 64 HRC. 9CRWMN section steel can be used to manufacture small cross-sections. The complex shape of Die, as well as various measuring tools. Commonly used in the stamping die, stamping die, bending die, drawing die, punch and finishing molds Mould.

9CrWMn material steel has a little crack sensitivity. It is not suitable to heat up quickly during forging heating. It is best to perform preheating at 650-750 degrees. The forging heating temperature is 1130-1150 degrees. The final forging temperature should be greater than 800-850 degrees. When forging, it is better to use the maximum temperature.

9CrWMn Grade:

| Country | China | Japan | Germany | USA | UK |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 | BS 4659 |

| Grade | 9CrWMn | SKS3 | 1.2510/100MnCrW4 | O1 |

Chemical composition (%)

| Grade | C | Mn | P | S | Si | Cr | V | W |

| O1 | 0.85-1 | 1-1.4 | 0.03 | 0.03 | 0.1-0.5 | 0.4-0.7 | 0.3 | 0.4-0.6 |

| 1.251 | 0.9-1.05 | 1-1.2 | 0.03 | 0.03 | 0.15-0.35 | 0.5-0.7 | 0.05-0.15 | 0.5-0.7 |

| SKS3 | 0.9-1 | 0.9-1.2 | 0.03 | 0.03 | 0.35 | 0.5-1 | _ | 0.5-1 |

Features

The 9CrWMn die steel is low-alloy cold-work die steel. The steel has certain hardenability and wears resistance. Small quenching deformation, uniform carbide distribution and fine particles.

9CrWMn die steel is usually used to manufacture cold stamping dies with small cross-sections and complex shapes. As well as various gauges and measuring tools.

Mechanical properties

Hardness: Annealing: 241~197HB, indentation diameter 3.9~4.3mm;

Quenching: ≥62HRC. 800~830℃. Oil cooling.

Forging process

The lower limit temperature is taken when the blank is forged

Annealing process

- 1 )Preheat: Warm slightly before charging into the preheat furnace, which should be operating at about 1100°-1200°F.

- 2) Hardening: Heat to 1475 to 1500° F. Soak at heat for 30 minutes per inch of thickness.

- 3) Quench: Quench O1 steel in warm oil and allow to cool in the oil until a temperature of 125°-150°F has been reached, or to where the part can be held in the bare hand, and temper immediately.

- 4) Temper: Normally oil hardening steels need to be single tempered only. However, double tempering may sometimes be preferred. Soak at heat for 2 hours per inch of thickness for each temper. Air cool to room temperature between tempers. The normal tempering range for this grade is 300 to 450° F.

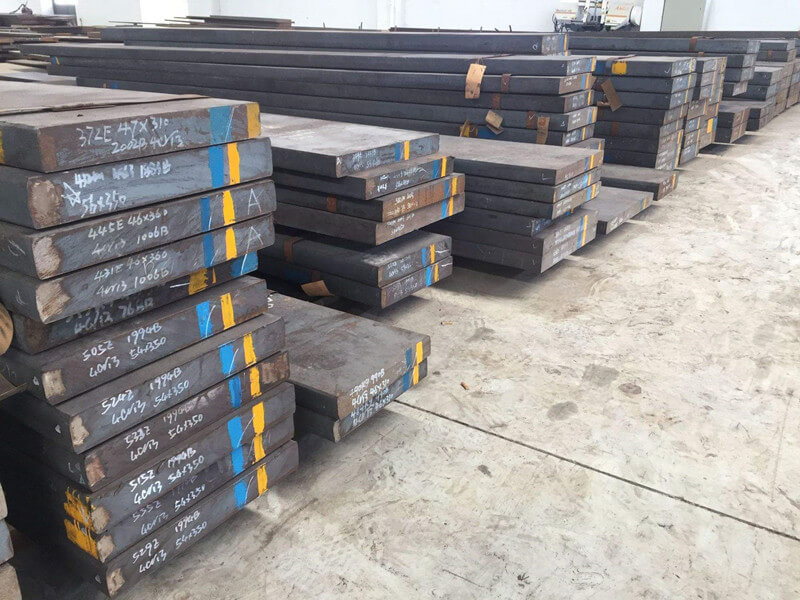

Available Size

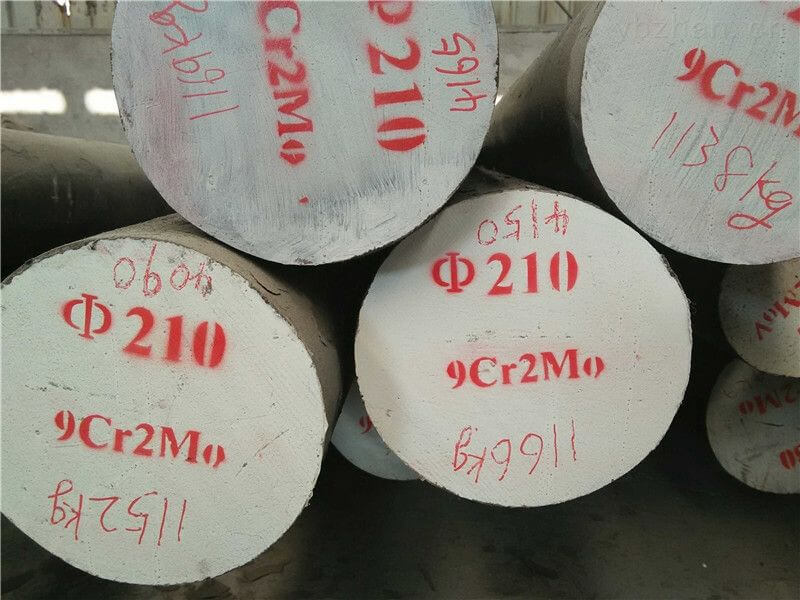

- Round Bar: Diameter(mm): 6-800mm ,Length: 1000-9000mm

- Plate/Flat/Block: Thickness: 6mm-500mm , Width: 20mm-1000mm

9CrWMn Steel Application

- 1) Used to make cold stamping dies with irregular cross-sections and more complex and high-precision shapes

- 2) Can be used to make thin stamping die, decorative embossing die, etc.

- 3) It is mostly used to make deformed and complex cutting tools. Such as long taps, long reamers, special milling cutters.

- 4) For integrally hardened plastic molds

- 5) Used for thermosetting plastic forming molds. Molds requiring high wear resistance and high strength

Delivery condition

- For hot forged or hot rolled bar: the delivery condition is hot forged or rolled, annealed, rough turned.

- For hot forged plate: the delivery condition is hot forged, annealed, milled surface.

- For hot rolled plate: the delivery condition is hot rolled, annealed, black surface.