Description

SM55 steel is a carbon plastic mold steel. Its chemical composition is like that of high-strength medium-carbon high-quality structural steel-55 steel. But steel is cleaner. The fluctuation range of carbon content is narrower. The mechanical properties are more stable. The steel has a high surface hardness, strength, wear resistance and certain toughness after heat treatment. Generally, it is used after normalizing or quenching and tempering.

SM55 Steel Chemical Composition

| C | Si | Mn | P | S |

| 0.52~0.58 | 0.17~0.37 | 0.50~0.80 | ≤0.030 | ≤0.030 |

SM55 Steel Mechanical Properties

| Proof Strength Rp0.2(MPa) | Tensile Strength Rm(MPa) | Impact Energy KV(J) | Elongation at fracture A(%) | Reduction in Cross Section on fracture Z(%) | As-Heat-Treated Condition | Brinell Hardness(HBW) |

| 229(≥) | 762(≥) | 12 | 12 | 32 | Solution and Aging, Annealing,Ausaging, Q+T | 343 |

SM55 Steel Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Modulus of elasticity kN/mm2 |

| 149(≥) | 585(≥) | 34 | 12 | 131 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Thermal conductivity W/mK | Electric resistance µΩ·cm |

| 859 | 892 | 559 | 43 | Solution and Aging, Annealing,Ausaging, Q+T |

Heat Treatment

Thermal processing

The starting temperature is 1180~1200°C. The end temperature is ≥800°C, air cooling, and the thickness >200mm should be cooled slowly.

Annealing

Annealing temperature 770 ~ 810 ℃. Slow furnace cooling.

High temperature tempering

Tempering temperature 680~720℃. Air cooling.

Normalizing

Normalizing temperature 810~860℃. Air cooling.

Quenching, tempering

1) Quenching temperature (850±10)℃. Oil cooling, tempering temperature 560℃, air cooling.

Heat treatment mechanical properties: tensile strength 650Mpa, yield strength 385Mpa, elongation 13%, impact toughness ≥35J/cm2.

2) Quenching temperature 790~830℃. Water cooling, hardness 58HRC.

| Tempering temperature/℃ | 200 | 300 | 400 | 500 | 550 | 600 | 650 |

| Tempering hardness/HRC | 57 | 50 | 45 | 35 | 30 | 24 | 23 |

Application

- 1) Used for larger plastic molds with general performance requirements.

- 2) For mold parts that do not require heat treatment.

- 3) For less precise mold quenching parts.

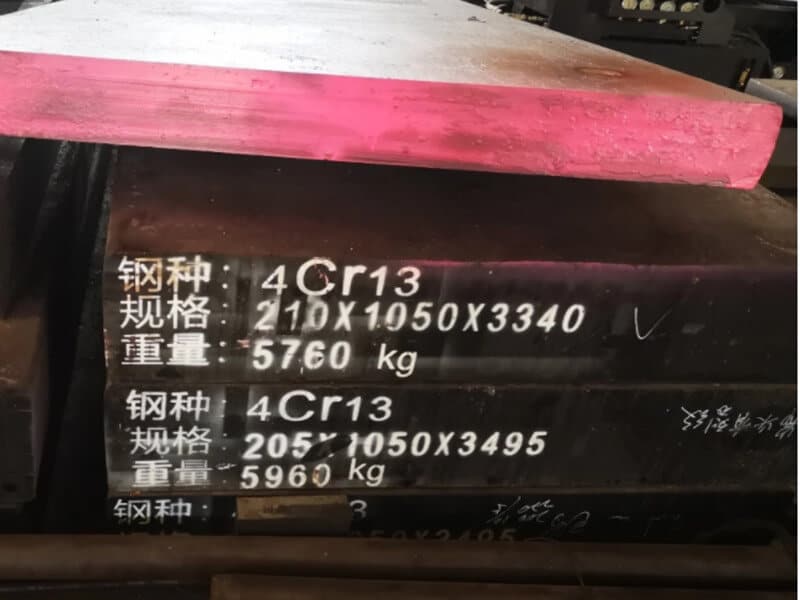

SM55 products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |