Description

4CrW2Si impact-resistant tool steel. 4CrW2Si can be used as cold work mold steel as well as hot work mold steel. 4CrW2Si alloy tool steel is made by adding 2.00% to 2.50% tungsten on the basis of chromium silicon steel. So, while having a certain hardenability and high-temperature strength, it may get higher toughness in the tempered state.

4CrW2Si Steel Worldwide Equivalents

| / | China | Kr | Russia | Japan |

| Standard | GB | K5 | roct | JIS |

| Grade | Cr12MoV | STS41 | 4xH2C | SKS41 |

4CrW2Si Steel Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | V | W | Cu |

| 0.35~0.45 | 0.80~1.10 | ≤0.40 | ≤0.030 | ≤0.030 | 1.00~1.30 | ≤0.20 | ≤0.20 | 2.00~2.50 | ≤0.30 |

4CrW2Si Steel Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross-section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 731(≥) | 662(≥) | 21 | 43 | 43 | Solution and Aging,Annealing, Ausaging,Q+T | 412 |

4CrW2Si Steel Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 492(≥) | 154(≥) | 44 | Solution and Aging,Annealing, Ausaging,Q+T | 321 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Specific heat J/kgK | Thermal conductivity W/mK |

| 894 | 785 | 746 | 14 | 23 |

Heat Treatment

- The transformation points of 4CrW2Si steel are Ac1-780°C, Ac3-840°C, Ms-315°C. The initial forging temperature of 4CrW2Si steel is 1100~1140℃. The final forging temperature is 800℃. Slowly cool down after forging. The common heat treatment process of 4CrW2S steel.

- Incomplete annealing is heated at 800~820°C. After holding for 1~-2h, the furnace is cooled to below 550°C and air-cooled. Hardness: 179~229HBS, heating temperature should be between Ac1~Ac3. To get granular pearlite structure.

- Stress relief annealing is heated at 710~740℃. After holding for 1~2h, it is cooled to below 500℃ with the furnace and air-cooled. The hardness is less than 269HB. The heating temperature should be below Ar1 to eliminate residual stress and eliminate work hardening.

- Quenching preheating 700~750°C, heating 870~900°C, heat preservation, oil cooling. The hardness is 52~57HBS, and the quenching heating temperature is higher than Ac3. Increase the secondary hardening effect

- Tempering heating 200~250°C. Heat preservation 2h. Air cooling heating 430~470°C, heat preservation 2h, air. The hardness is 53~58HRC, 45~50HRC. Emphasize the hardness to take the lower limit. Emphasize the toughness to take the upper limit.

Features and Application

- It is used to make tools that withstand high impact loads. Such as punching and trimming composite molds. Scissors for cold cutting.

- After carbon quenching, it can be used to make heavy-duty cold-punching dies, medium and heavy-duty cold-punching punches and precision pressing dies

- The steel is a cold and hot work die steel commonly used by countries all over the world.4). It is used to make the shovel of the cold cut metal, the shovel of the shovel rubbing board, the die of the cold blanking and trimming, the top die and the punch, the cutting, etc.

- It is the basic material of various punching and shearing tools, precision pressing dies, and cold heading dies.

- It is suitable for shearing machines and wind-driven tools with heavy shock and vibration.

- Applicable to small thermal molds

- It can be used for the cavity block material and core material of the die-cast zinc alloy die. (Zinc alloy is often used, and the hardness is 40~48HRC.)

- It is suitable for medium-stress hot forging dies and die-casting dies with low heat exposure.

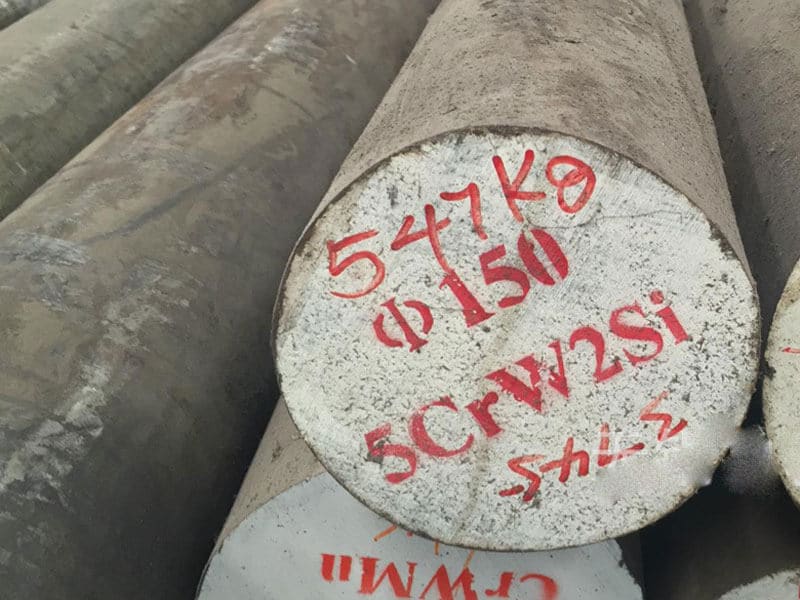

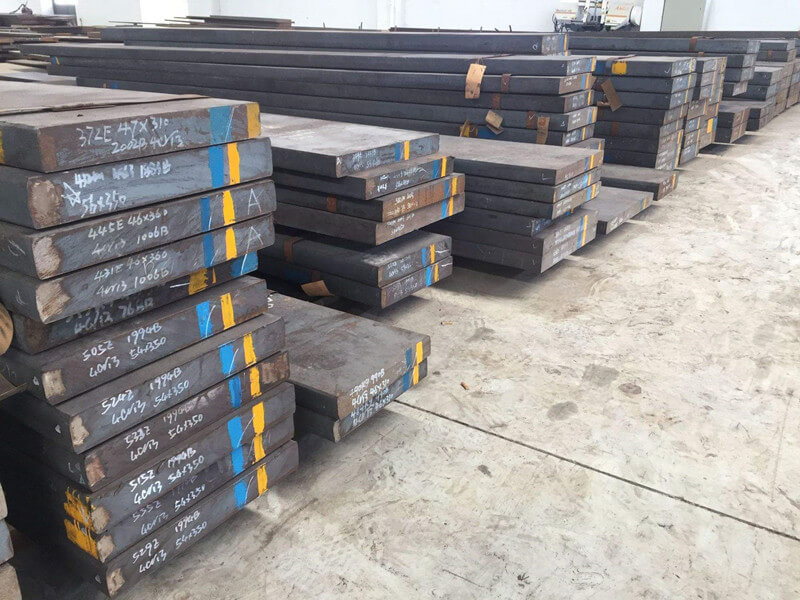

4CrW2Si Steel products

| Product type | Products | Dimension | Processes | Delivery Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Our Services

1. The price is determined according to the material, size, finishing process and different payment methods

2. Each material has been ut tested

3. We have every kind of material in stock, so we can deliver it in time.

4. The size of steel can be customized according to customer requirements, and the minimum order quantity and specification model can be developed / produced according to international, Chinese or industrial standards