Description

4Cr13 is stainless steel material with high hardness and high wear resistance. After quenching, it has higher hardness and good corrosion resistance than 3Cr13.

4Cr13 Worldwide Equivalents

| Country / Region | China | EU | Germany | Japan | USA |

| Standard | GB | EN | – | JIS | – |

| Grade | 4Cr13 | X39Cr13 (1.4031) | X39Cr13 | SUS420J2 | 420S45 |

4Cr13 Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Ni |

| 0.36~0.45 | ≤0.60 | ≤0.80 | ≤0.030 | ≤0.035 | 12.00~14.00 | ≤0.60 |

4Cr13 Mechanical Properties

- HRC hardness: ≥ 50 (Quenched and Tempered)

- HBW hardness: ≤ 235 (Annealed)

4Cr13 Physical Properties

- Density (g/cm3): 7.75

- Specific heat capacity (J/Kg·K): 460 at 0-100℃

- Thermal conductivity (W/m·K):

- 28.1 at 100℃

- 28.9 at 500℃

Coefficients of linear thermal expansion (10-6/K):

- 10.5 (0-100℃)

- 12.0 (0-500℃)

- Electrical Resistivity (μΩ·m): 0.59 at 20℃

- Longitudinal modulus of elasticity (kN/mm2): 215 at 20℃

Heat Treatment

Annealing:

750 to 800°C for about 2 to 5 hours

Slow controlled cooling of 10 to 20°C per hour to about 650°C;

Further cooling in air, max. 200 HB

Hardening:

1000 to 1050°C

15 to 30 minutes keeping curing temperature

Quenching in oil/compressed gas/hot bath

Obtainable hardness: 53 – 56 HRC

Tempering:

Slow heating to tempering temperature immediately after hardening, to 180 to 300 °C depending on desired hardness

1 hour per 20 mm: min. 2 hours

Features and Application

After quenching, the hardness is higher than that of 3Cr13, and the corrosion resistance is good. Quenching hardness is generally above HRC48.

Industrial using

Suitable for electric discharge and grinding, suitable for high-mirror and high-precision injection molds. After heat treatment, it has high hardness and toughness. It can also be used as stamping mold parts and templates. It is generally suitable for high-temperature anti-rust and anti-corrosion scenarios.

Civilian using

It can be used to make table knives and outdoor knives.

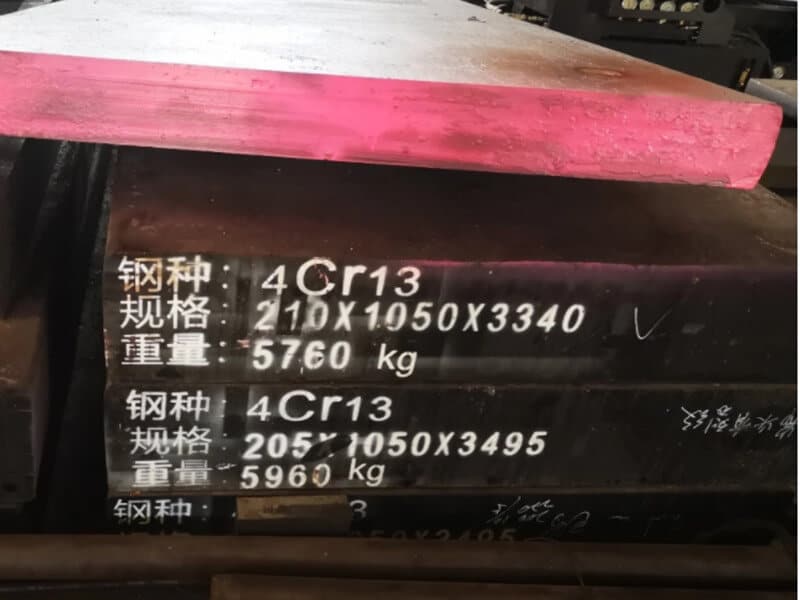

4Cr13 products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |