Description

4Cr5MoSiV1 steel for die casting molds. It has good toughness and good thermal strength, thermal fatigue properties and wear resistance. It can be hardened by air cooling, and the heat treatment deformation is small.

4Cr5MoSiV1 Worldwide equivalents

| – | China | USA | Germany | Japan |

| Standard | GB | ASTM | DIN | JIS |

| Grade | 4Cr5MoSiV1 | H13 | 1.2344 | SKD61 |

4Cr5MoSiV1 Chemical Composition

| C | Si | Mn | P (≤) | S (≤) | Cr | Ni (≤) | Mo | V | Cu(≤) |

| 0.32-0.42 | 0.8-1.2 | 0.20-0.50 | 0.030 | 0.030 | 4.7-5.5 | 0.20 | 1.1-1.75 | 0.80-1.20 | 0.30 |

4Cr5MoSiV1 Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 762(≥) | 969(≥) | 44 | 34 | 42 | Solution and Aging, Annealing, Ausaging, Q+T | 232 |

4Cr5MoSiV1 Physical Properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J/kgK | Thermal conductivity W/mK |

| 278(≥) | 143(≥) | 42 | 21 | 13 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0)N/mm2 | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 |

| 778 | 484 | 456 | Solution and Aging,Annealing,Ausaging, Q+T | 212 |

4Cr5MoSiV1 Steel Application

Suitable for aluminum and copper die-casting molds. hot extrusion molds, mandrel forging molds, plastic molds that work for a long time at high temperatures. Also suitable for heat-resistant thimbles, push rods and ejector pins.

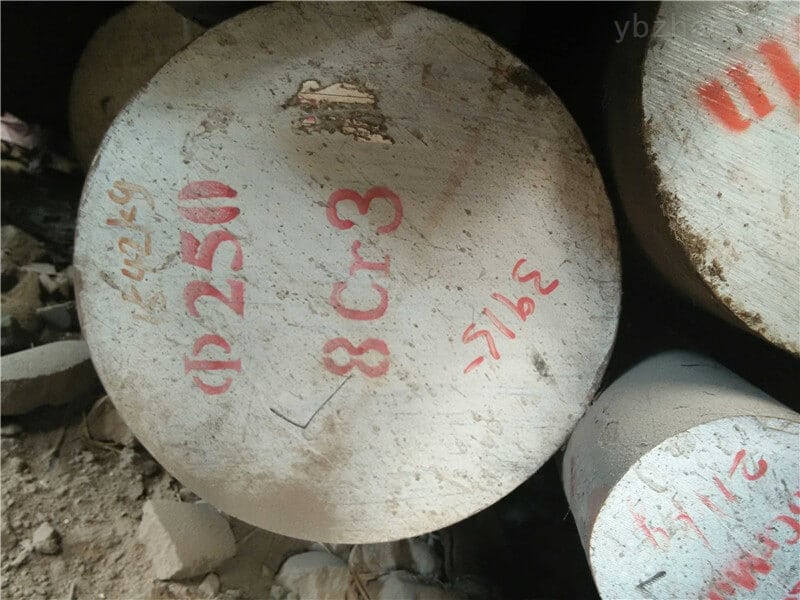

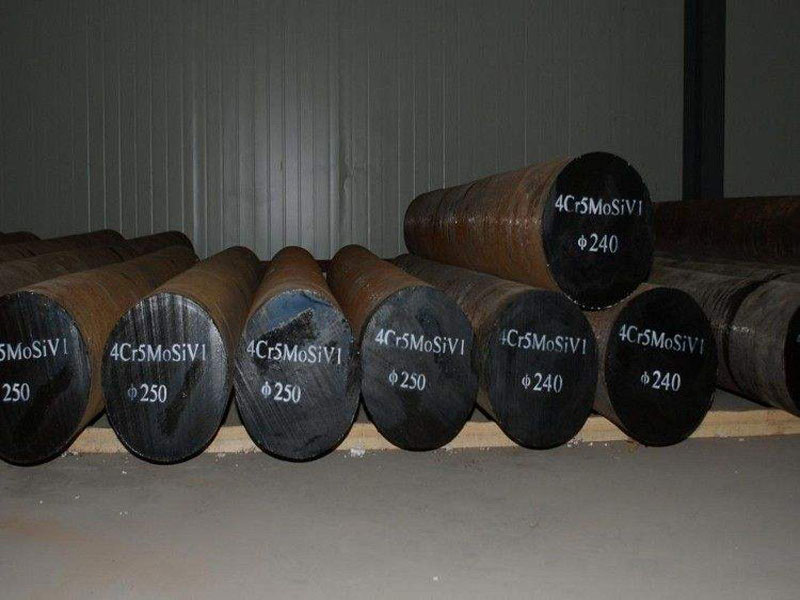

4Cr5MoSiV1 products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |