Description

4Cr5W2VSi steel is an air-cooled hardening hot work die steel. It has high thermal strength, hardness, wear resistance, toughness and good thermal fatigue performance at medium temperature.

When working, the temperature of 4Cr5W2VSi steel itself should not exceed 600 ℃

4Cr5W2VSi Chemical Composition

| C | Si | Mn(≤) | P (≤) | S (≤) | Cr | Ni (≤) | W | V | Cu(≤) |

| 0.32-0.42 | 0.8-1.2 | 0.40 | 0.030 | 0.030 | 4.5-5.5 | 0.20 | 1.6-2.4 | 0.6-1.0 | 0.30 |

4Cr5W2VSi Mechanical Properties

| Yield | Tensile | Impact | Elongation | |

| 385 (≥) | 381 (≥) | 22 | 34 | |

| Reduction in cross section on fracture | As-Heat-Treated Condition | Brinell hardness (HBW) | — | |

| 12 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 122 | — |

4Cr5W2VSi Physical Properties

| Yield | Tensile | Impact | Elongation |

| 385 (≥) | 381 (≥) | 22 | 34 |

| Reduction in cross section on fracture | As-Heat-Treated Condition | Brinell hardness (HBW) | — |

| 12 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 122 | — |

Heat treatment

Annealed after forging

The heating temperature is 860~880℃, the temperature is kept for 3~4h, and the furnace is cooled to below 500℃ and air-cooled. After annealing, the hardness is s229HBS, and the structure is pearlite + carbide.

Isothermal spheroidizing annealing

Heating temperature is 860℃, holding for 2~4h, isothermal temperature is 750℃, holding for 4~6h, furnace cooling to below 550℃, air cooling, hardness s229HBS, organization is spherical pearlite + carbide.

Stress relief annealing

The heating temperature is 750~780℃, the temperature is kept for 2~4h, and the furnace is cooled or air cooled.

4Cr5W2VSi Steel Application

4Cr5W2VSi steel is suitable for making dies and mandrels for hot extrusion, die-casting moulss for light metals. Such as aluminum and zinc, tools for hot forging structural steel and heat-resistant steel, and high-speed hammer forging molds for forming parts.

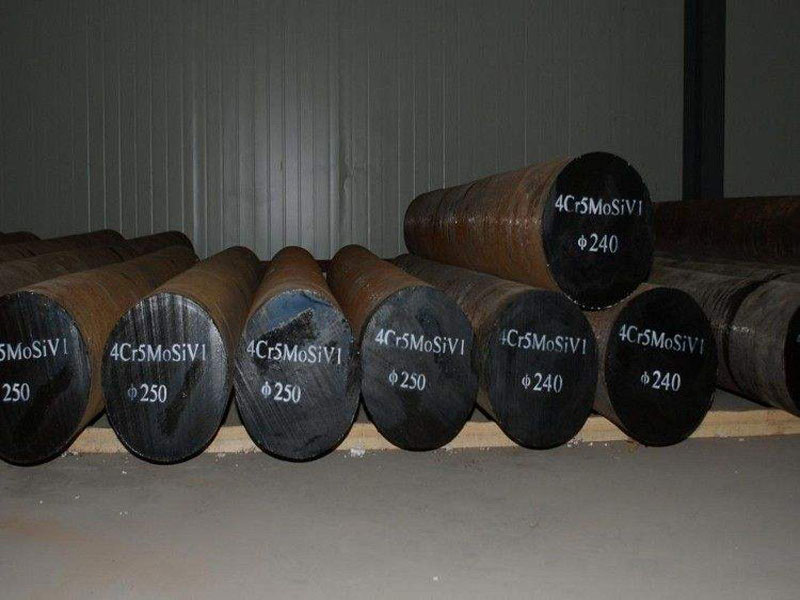

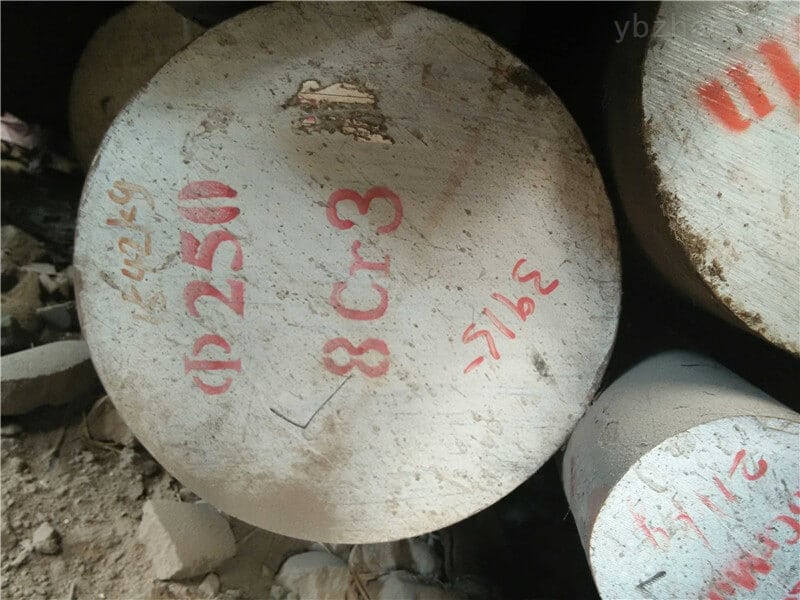

4Cr5W2VSi steel products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |