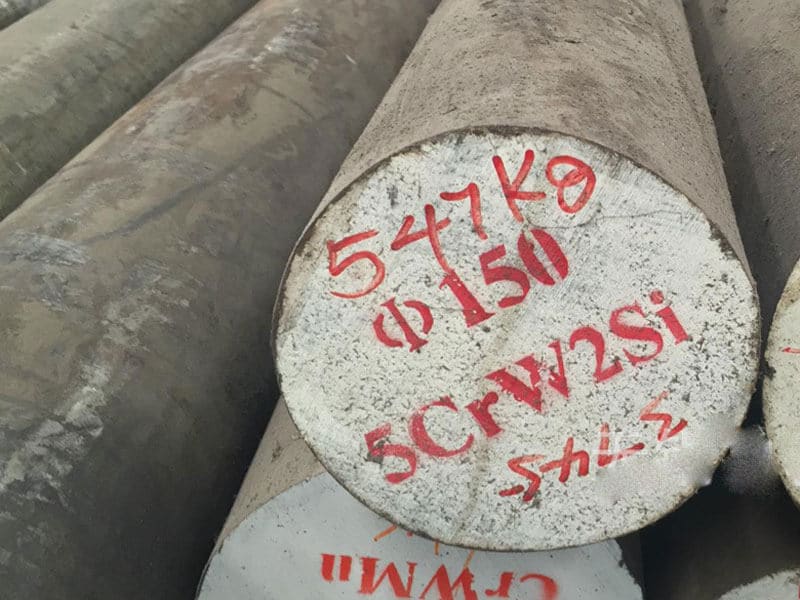

Description

5CrW2Si Mold steel belongs to steel impact-resistant tool steel. The composition and properties are like 4CrW2Si. 5CrW2Si is made by adding 2.00%~2.50% tungsten on the basis of chromium silicon steel. Thanks to the addition of tungsten, it helps to maintain relatively fine grains during quenching. This makes it possible to get higher toughness in the tempered state. Improve tempering stability. The steel also has certain hardenability and high-temperature mechanical properties.

5CrW2Si Worldwide equivalents

| / | China | French | Germany | England |

| Standard | GB | NF | D1N/DIN | BS |

| Grade | 5CrW2Si | 45WCrV8 | 45WCrW/ 1.2542 | BS1 |

| / | USA | Russia | ISO | Sweden |

| Standard | AS1M/UNS | roct | SS | |

| Grade | S1/T41901 | 5xB2C | 45WCrV2 | 2710 |

5CrW2Si Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Ni | Cu | W |

| 0.45-0.55 | 0.50-0.80 | ≤0.40 | ≤0.030 | ≤0.030 | 1.00-1.30 | allowable residual content ≤0.25 | allowable residual content ≤0.30 | 2.00-2.50 |

5CrW2Si Steel Mechanical Properties

| Yield Rp0.2 (MPa) | Tensile Rm (MPa) | Impact KV (J) | Elongation A (%) | Reduction in cross section on fracture Z (%) | As-Heat-Treated Condition | HBW |

| 413 (≥) | 385 (≥) | 12 | 11 | 11 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 343 |

5CrW2Si Steel Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J / kgK | Thermal conductivity W/mK |

| 994 (≥) | 291 (≥) | 14 | 41 | 34 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0) N/mm2 | Creep rupture strength (10000h) (Rp1,0) N/mm2 | Electric resistance µΩ·cm | – |

| 478 | 363 | 884 | Solution and Aging, Annealing, Ausaging, Q+T | – |

Heat Treatment

Steel ingot: heating temperature 1180~1200℃, initial forging temperature 1150~1170℃, final forging temperature ≥850℃, slow cooling.

Billet: heating temperature 1150~1180℃, initial forging temperature 1120~1150℃, final forging temperature ≥850℃, slow cooling.

Normal annealing specification:

Temperature 800~820℃ Critical point temperature (approximate value) Ac1=755℃, holding time 3~4h, and then slowly cooling to temperature ≤600~650℃ at a cooling rate of ≤30℃/h, and then air cooling out of the furnace. Heat treatment specification: sample quenching 860~900℃, oil cooling.

The high temperature tempering specification temperature is 710~740℃, after soaking, the holding time is 3~4h, and then the furnace is cooled or the furnace is air cooled.

The standard temperature of isothermal annealing is 750~760℃, holding for 8~10h, and then slowly cooling to temperature ≤650℃ at a cooling rate of 10~20℃/h, and then air cooling out of the furnace. The hardness is 207~235HBS, and better processing performance can be obtained.

Features and Application

- 1、Manufacturing blades for cutting metal, shovel blades for shoveling and rubbing wire boards, die for cold blanking and edge trimming, etc.

- 2、Manufacturing large and medium-sized heavy-duty round shear blades, long shear blades, and shaped shear blades.

- 3、Manufacturing punch punches for medium and thick steel plates, precision pressing dies, cold heading dies, etc.

- 4、Making manual and pneumatic chisels, air hammer tools, rivet tools, and cold punching dies.

- 5、When used as hot processing steel, it can be used for punching, piercing tools, shearing dies, hot forging dies, and die-casting dies of fusible alloys.

- 6、Manufacture of metal cutting blades and shovel blades for shoveling and rubbing wire plates.

- 7、Die for cold blanking and trimming.

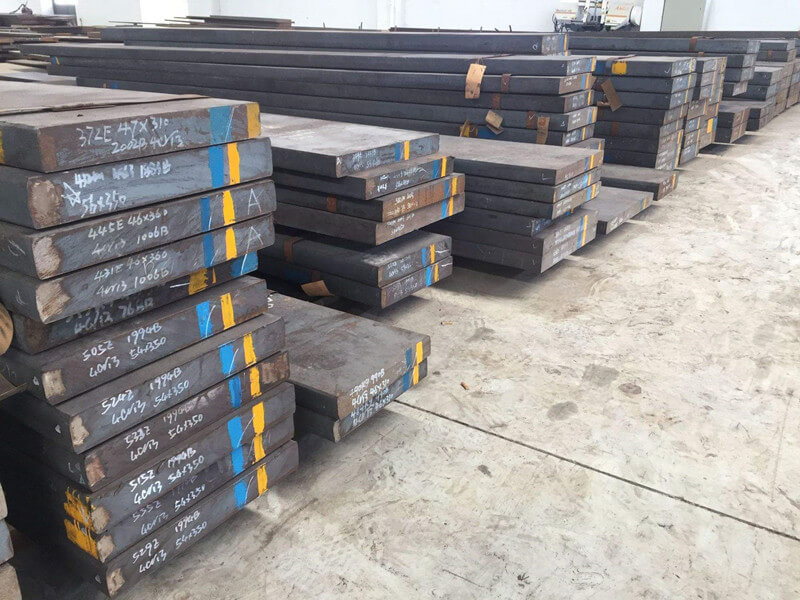

5CrW2Si Steel products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |