Description

T11 steel has good comprehensive mechanical properties of hardness, wear resistance and toughness. Such as strength, hardness, wear resistance and toughness. . Its carbon content is between T10 and T12.

T11 Steel Worldwide Equivalents

| / | China | Kr | Germany | Japan | England |

| Standard | GB | KS | DIN,WNr | JIS | BS |

| Grade | T11 | STC3 | C110w2/C105W1 /1. 1654 | SK105 | 1407 |

| / | France | IOS | USA | Russia | |

| Standard | AFNOR/NF | – | AISI/sAE | roct | |

| Grade | Y1150/C105E2U | TC105 | W1A-10(1/2) | Y11 |

T11 Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Ni | Cu |

| 1.05 | ≤0.35 | ≤0.40 | ≤0.030 | ≤0.035 | Allowable residual content ≤ 0.25, ≤ 0.10 (when manufacturing lead bath quenched steel wire) | Allowable residual content ≤ 0.20, ≤ 0.12 (when manufacturing lead bath quenched steel wire) | Allowable residual content ≤ 0.30, ≤ 0.20 (when manufacturing lead bath quenched steel wire) |

Heat Treatment

Heat Treatment:

The sample is quenched at 760~780℃. Water-cooled.

Ordinary annealing

The cooling temperature is 750~760°C. Insulation for 2~4h, and then cooling to 500~600°C with the furnace at a cooling rate of <30°C/h, and then air-cooled.

Isothermal spheroidizing annealing

- 1) 750~760°C×2 –4h. 680~700°C×4~6h, then furnace cooled to 500~600°C, air-cooled, hardness ≤197HBW.

- 2) 750~770°C×1~2h, 680~700°C×2~3h, hardness 163~197HBW, pearlite structure grade 1-5.

Tempering treatment

Quenching temperature 790 ~ 810°C. Oil cooling, return temperature 640 ~ 680°C, heat preservation 2 ~ 3h, hardness 183 ~ 207HBW.

Quenching and tempering treatment specification

Quenching temperature 760~780°C. Water cooling, oil two-liquid cooling or alkali bath cooling. hardness≤62HRC, return to temperature.

Features

该钢的优点是可加工性好, 具有高硬度与韧性, 但淬透性低, 淬火变形大。因钢中含合金元素少, 耐回火性低, 硬化层浅, 因而承载能力较低。具有较高的硬度和耐性, 晶粒长大敏感性小。

The steel has the advantages of good machinability, high hardness and toughness, but low hardenability and large quenching deformation. The bearing capacity of the steel is low because it contains less alloy elements, low resistance to re ignition and shallow hardening layer. It has high hardness and resistance, and is less sensitive to grain growth.

Applications

1) It is suitable for making tools with high hardness and wear resistance without severe impact. Such as scrapers and cold punching dies.

2) It is suitable for all kinds of small and medium production batch molds and shock-resistant molds.

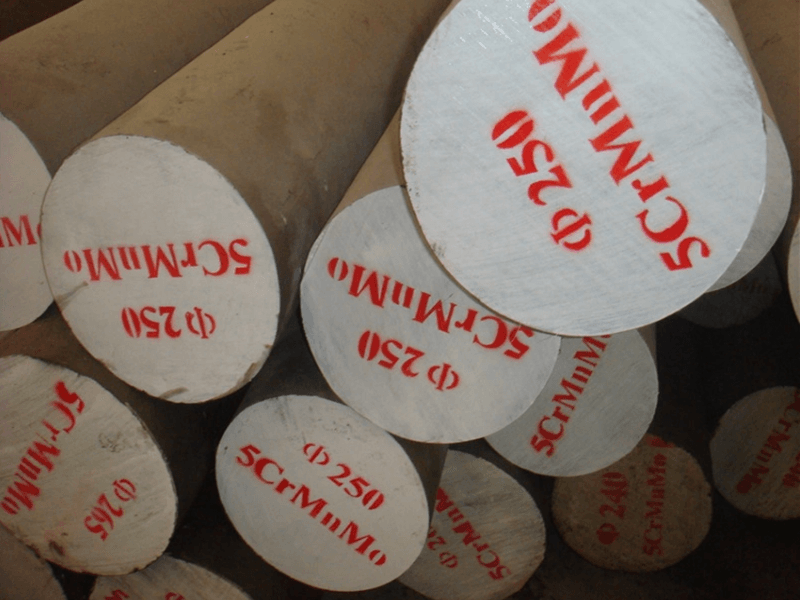

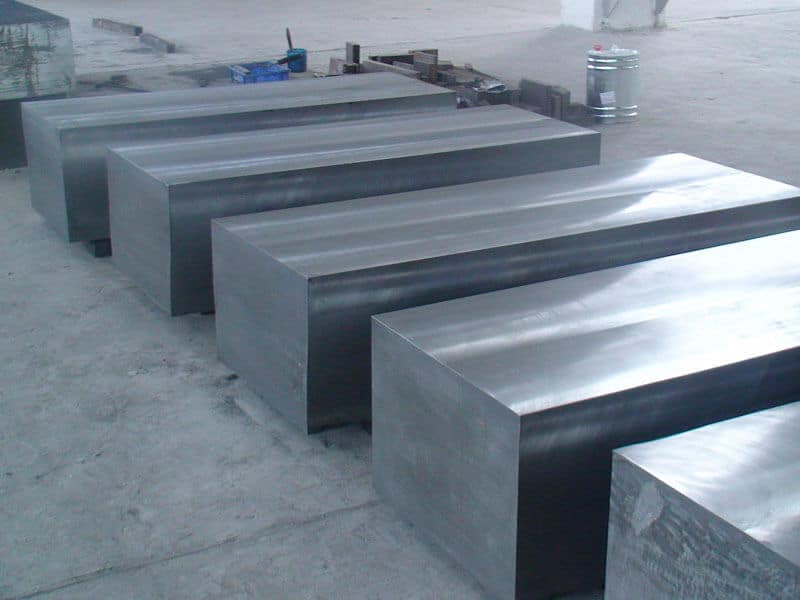

T11 Products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |