Description

T12 steel is a kind of steel with relatively high carbon content. There are more excess carbides after quenching. Its wear resistance and hardness are suitable for making products that are not subject to impact load, low cutting speed, and cutting edge that does not heat up tool.

T12 Worldwide equivalents

| / | China | Sweden | Germany | Japan | France | England |

| Standard | GB | B5 | DIN,WNr | JIS | AFNOR/ NF | B5 |

| Grade | T20 | 1885 | C125W2/1.1663 | SK120 | Y2120/C12E3U | STC2 |

| / | Spain | USA | USA | Russia | Inter | Italy |

| Standard | UNE | ASTM/AISI/SAE | UNS | r0CT | ISO | UNI |

| Grade | C120 | W1A-11/frac12 | T72301 | Y12 | TC120 | C120KU |

T12 Steel Chemical Composition

| C(%) | Si(%) | Mn(%) | P(%) | S(%) |

| 1.15-1.24 | ≦0.35 | ≦0.4 | ≦0.035 | ≦0.03 |

T12 Treatment Process

Normalizing

Normalizing temperature 850~870°C. Air cooling, hardness 269~341HBW

Ordinary annealing

Annealing temperature is 760 ~ 770°C. Hold for 2 ~ 4h. Then, at a cooling rate of <30°C/h, slowly cool to 500 ~ 600°C with the furnace, and then release the furnace for air cooling.

Isothermal spheroidizing annealing

1) 760 ~770 ℃ ×2 ~4h, 680~700 ℃ ×4 ~6h. After isothermal, furnace cooling temperature to 500 ~600 ℃, and then air cooling, hardness≤207HBW

2) 750~770 ℃×1~2h, 680~700 ℃×2 –3h, hardness 179~207HBW.

Tempering treatment

Quenching temperature 800~820 ℃. Oil cooling; tempering temperature 640~680 ℃, holding time 2~3h, spheroidization grade: 3~5 grade, hardness 183~207HBW.

Ordinary quenching and tempering

Quenching temperature 760~780 ℃. Water cooling, water-oil two-liquid cooling or alkali bath cooling. Hardness ≤62HRC, tempering temperature (180 ±10) ℃.

T12 Steel Application

- 1. Make cold drawing and deep drawing die.

- 2. Make small drawing, deep drawing and extruding dies.

- 3. It can be used for cold working die with small size, simple shape and light load, such as small punch, scissors of shearing machine.

- 4. Make some cold stamping dies that need that the hardened layer is not deep and maintain high toughness.

- 5. It is suitable for various small and medium production batches of molds and shock-resistant molds.

- 6. Carbon tool steel is only suitable for making plastic molds with small size, small force, simple shape and low deformation requirements.

- 7. It is used for guidepost, guide sleeve, push plate guide post and push plate guide sleeve.

- 8. Diagonal pins, sliders, locking wedges for plastic molds,

- 9. For push rod and push tube

- 10. For feeding chamber and plunger

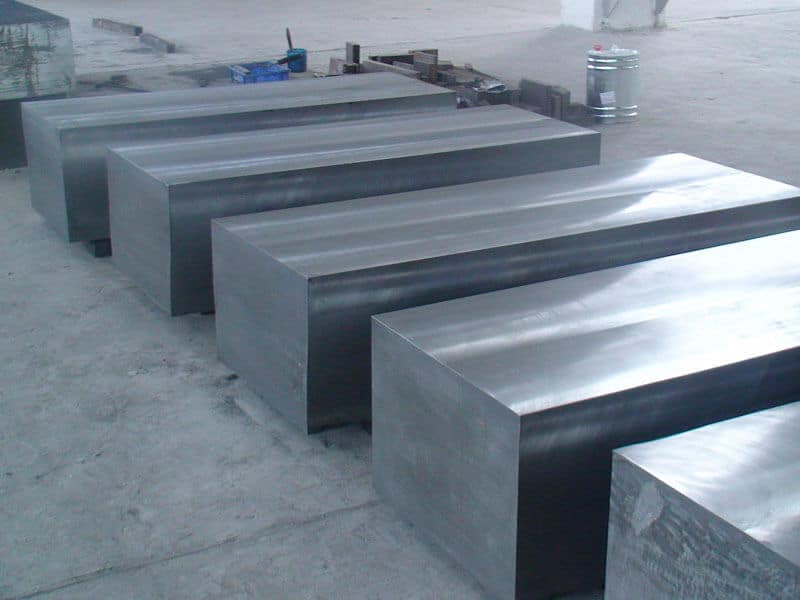

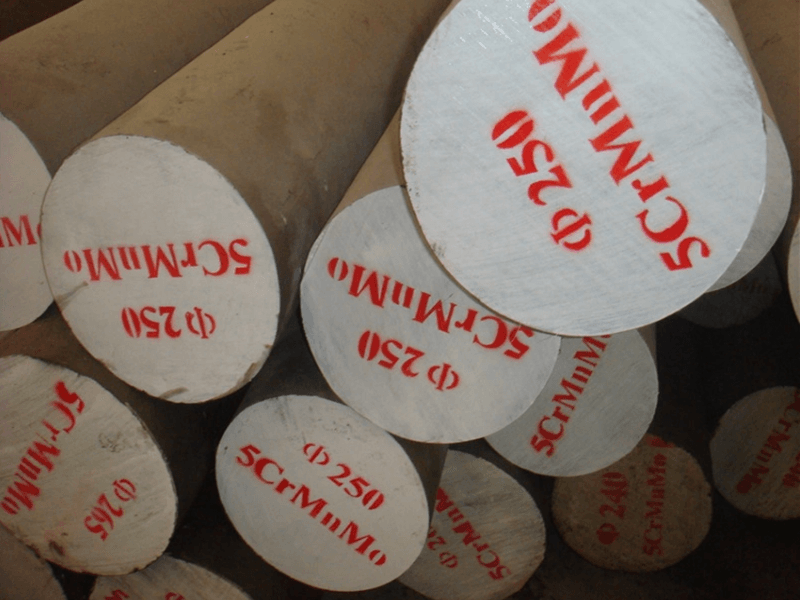

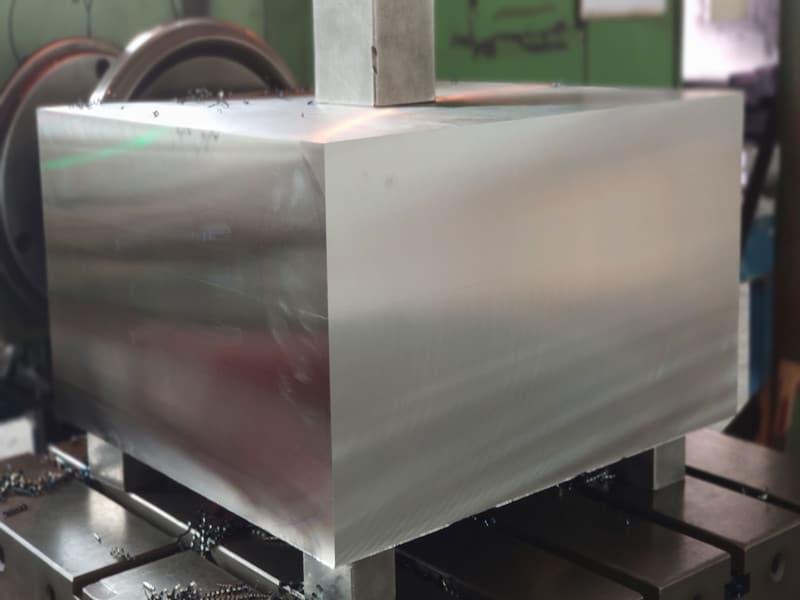

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |