Description

Cr6WV is a medium alloy cold work mold steel with good comprehensive properties. The steel has small deformation and good hardenability. It has good wear resistance and certain impact toughness.

Cr6WV Steel Worldwide Equivalents

| / | China | USA | Germany | Japan | Sweden |

| Standard | GB | AISI/SAE | DIN,WNr | JIS | AFNOR |

| Grade | Cr6WV | A2 | X100crmov51/ 1.2363 | SKD12 | XW-10 |

Chemical Composition

| C | Si | Mn | Cr | W | V | P | S |

| 1.00~1.15 | ≤0.40 | ≤0.40 | 5.50~7.00 | 1.10~1.50 | 0.50~0.70 | ≤0.030 | ≤0.030 |

Cr6WV Steel Physical Properties

Critical temperature of cr6wv steel

| critical point | Ac1 | Acm | Ar1 | Arm | Ms | Mf |

| Temperature (approximate) / ℃ | 815 | 845 | 625 | 775 | 150 | -100 |

Linear expansion coefficient of cr6wv steel

| Temperature / ℃ | 100~250 | 250~350 | 350~600 |

| Expansion coefficient / ℃ – 1 | 10.3×10﹣6 | 10.3×10﹣6 | 10.3×10﹣6 |

Heat Treatment

General annealing

The heating temperature is 830-850 degrees, the furnace is cooled to below 550 degrees, and the furnace is air-cooled. The hardness after annealing is 229HBW.

Warm annealing process

Heating temperature 830-850 degrees, isothermal temperature 700-720 degrees. Furnace cooling to 550 degrees air cooling, Hardness ≤ 229HBW. Annealing metallographic structure is fine granular pearlite + carbide.

Quenched and tempered at low temperature. (960~980 degree oil quenching, 200~300 degree tempering). After tempering, it contains carbides with a mass fraction of about 8% to 10%. The mass fraction of retained austenite is 15% to 20%.

The tempering temperature is 150~170 degrees. The hardness is 62~63HRC. The tempering temperature is 190~210 degrees. The hardness is 58~60HRC.

Features and Application

Cr6WV steel has a wide range of uses. Manufacture of molds with high mechanical strength, wear-resistance and shock loads. Such as drill sleeves, cold mold and punches, trimming dies, stamping dies, thread rolling dies, and thread rolling plates.

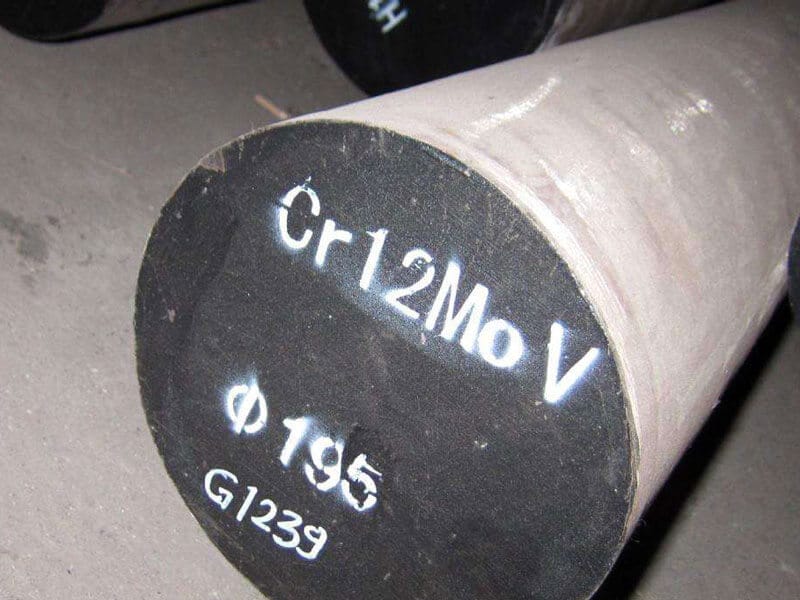

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |