Description

T9 steel is a high-grade carbon tool steel, cold work die steel. It is high carbon steel with a carbon content of more than 0.6%. The steel has high hardness and wear resistance. Medium toughness.

T9 Steel Worldwide Equivalents

| / | China | Japan | USA | Russia | IOS |

| Standard | GB | JIS | AISI/SAE | roct | – |

| Grade | Cr12MoV | SK4 | W1A-8 1/2 | Y9 | TC90 |

T9 Steel Chemical Composition

| C | Si | Mn | S | P | Cr | Ni | Cu |

| 0.80-0.90 | ≤0.35 | ≤0.50 | ≤0.030 | ≤0.035 | ≤0.20 | ≤0.25 | ≤0.30 |

T9 Steel Mechanical Properties

| Proof strength Rp0.2 (MPa) | Tensile strength Rm (MPa) | Impact energy KV (J) | Elongation at fracture A (%) | Reduction in cross section on fracture Z (%) | As-Heat-Treated Condition | Brinell hardness (HBW) |

| 937 (≥) | 768 (≥) | 13 | 42 | 13 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 314 |

T9 Steel Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Specific heat J / kgK | Modulus of elasticity kN/mm2 |

| 219 (≥) | 894 (≥) | 31 | 33 | 324 |

| Temp. °C/°F | Creep strain limit (10000h) (Rp1,0) N/mm2 | Creep rupture strength (10000h) (Rp1,0) N/mm2 | Thermal conductivity W/mK | Electric resistance µΩ·cm |

| 634 | 615 | 392 | 23 | Solution and Aging, Annealing, Ausaging, Q+T,etc |

Heat Treatment

Ordinary annealing

(740-750)°C×(2-4)h. With a cooling rate of <30°C/h, slowly furnace-cool to a temperature of 500-600°C, and air-cool the furnace.

Isothermal spheroidizing annealing

(740-750) ℃ × (2-4) h. (650-680) ℃ × (4-6) h, after furnace cooling to 500-600 ℃, air cooling, hardness ≤ 192HBS.

Quenching, tempering

The quenching temperature is 770-790℃. Water cooling, water-oil double-liquid cooling or alkali bath cooling, quenching hardness 62HRC. The tempering temperature is 180±10℃.

Application

1. It is suitable for various small and medium batch production molds. Such as cold heading punches.

2. Tools for impact load resistance, such as scrapers.

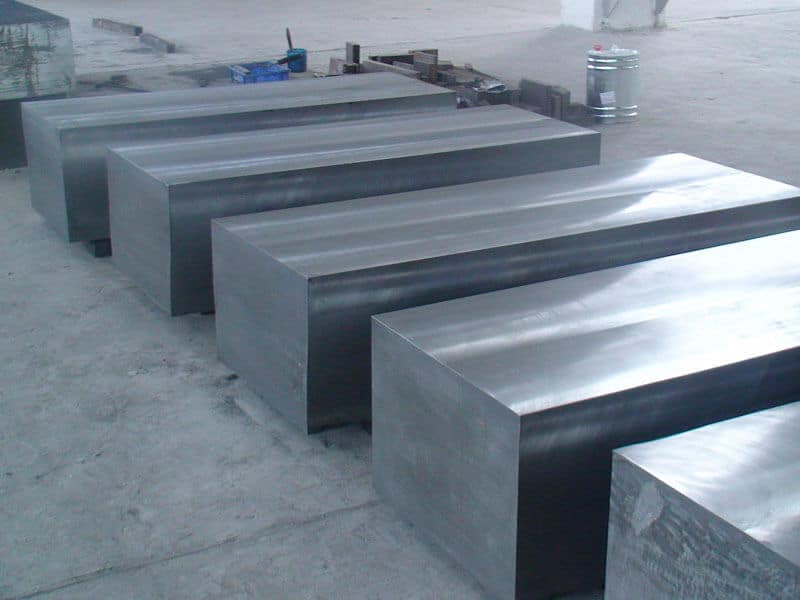

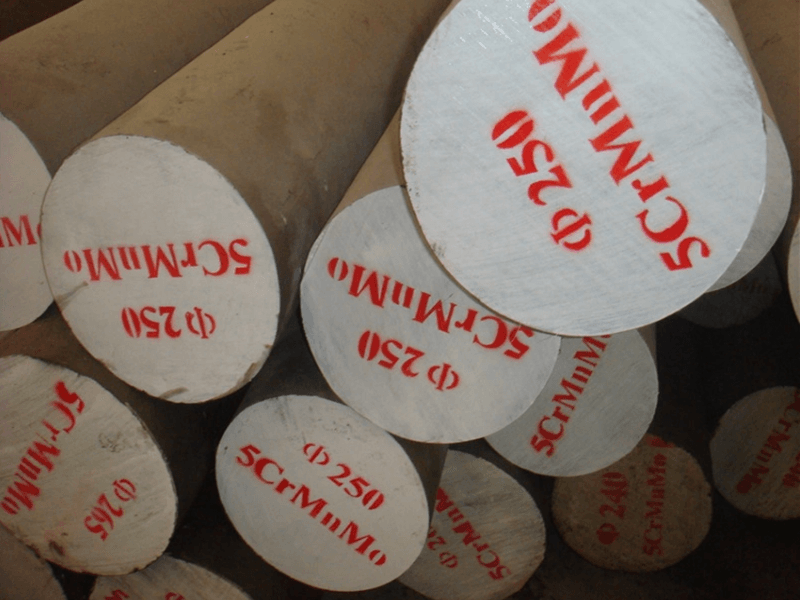

T9 products

| Product type | Products | Dimension | Processes | Delivery States |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |