Description

Cr12 mold steel belongs to high carbon and high chromium ledeburite steel. It is also a widely used cold work die steel. The steel has good hardenability, wear resistance, and hot workability. Carbides are well distributed in steel. It can be used to manufacture various cold work molds with complex shapes and heavy working conditions.

Worldwide equivalents of grade: Cr12

| country / region | China | EU | Germany | Japan | France | England |

| Standard | GB | EN | DIN, WNr | JIS | AFNOR | BS |

| Grade | Cr12 | X210Cr12 (1.2080) | X21Cr12 | SKD1 | Z200C12 | BD3 |

| country / region | Poland | Czechia | Austria | Russia | Inter | |

| Standard | PN | CSN | ONORM | GOST | ISO | |

| Grade | NC11 | 19436 | K100 | KH12 | X12Cr12 |

Chemical Composition of Cr12 Steel Material(%)

| C | Si | Mn | S | P | Cr | Co |

| 2.00-2.30 | 0.40 MAX | 0.40 MAX | 0.30 MAX | 0.30 MAX | 11.50-13.00 | 1.00 MAX |

Cr12 steel Mechanical Properties

| Elongation at fractureA (%) | Reduction in cross section on fractureZ (%) | As-Heat-Treated Condition | Brinell hardness (HBW) | Proof strengthRp0.2 (MPa) | Tensile strength Rm (MPa) | Impact EnergyKV (J) |

| 42 | 31 | Solution and Aging, Annealing, Ausaging, Q+T | 142 | 318 (≥) | 267 (≥) | 32 |

Cr12 steel Physical Properties

| Property | Densitykg/dm3 | Temperature T°C/F | Electric resistanceµΩ·cm | Modulus of elasticitykN/mm2 |

| 357 (≥) | 234 (≥) | 33 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 234 |

| Temp.°C/°F | Creep strain limit(10000h)(Rp1,0) N/mm2 | Creep rupture strength(10000h)(Rp1,0) N/mm2 | Specific heatJ / kgK | Thermal conductivityW/mK |

| 897 | 524 | 537 | 23 | 33 |

Heat Treatment

Annealing:

3CR12 is supplied in the annealed condition, its softest and most ductile state. After severe cold forming operations or after hot forming operations above 750oC, annealing may be required. Annealing is carried out at 700-750oC followed by air cooling.

Soaking times are 12hours per 25mm section.

Stress Relieving:

Stress relieving is not recommended for 3CR12. If it is essential, temperatures of not more than 450oC should be employed.

Hot Forming:

Any hot forming should preferably be conducted at temperatures below 750oC. The recommended temperature range is between 600oC and 700oC and annealing should be performed after forming.

Features and Application:

Cr12 is an alloy tool steel. It has high strength, good hardenability, and good wear resistance. It is mainly used as a mold with low impact load and high wear resistance. Such as cold punching dies and punches, cold cutting scissors. Drill sleeves, gauges, drawing dies, stamping dies, thread rolling boards, thread rolling dies.

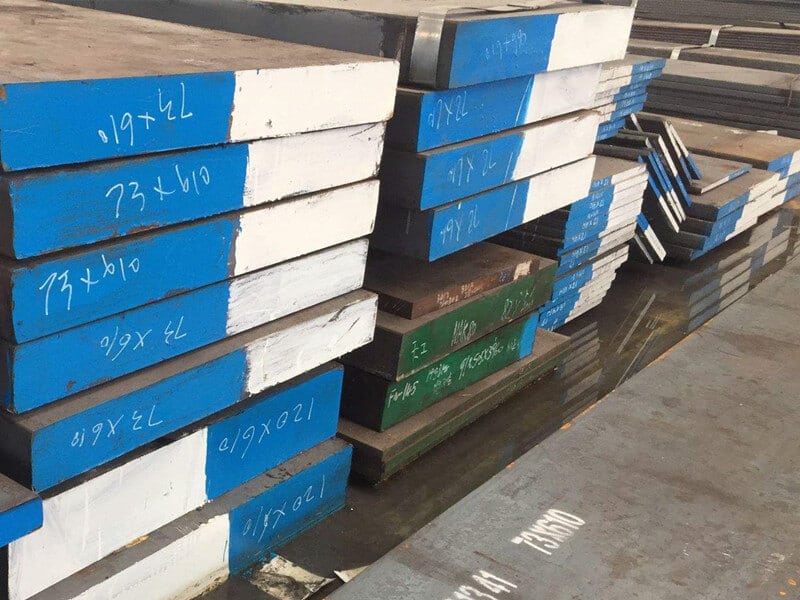

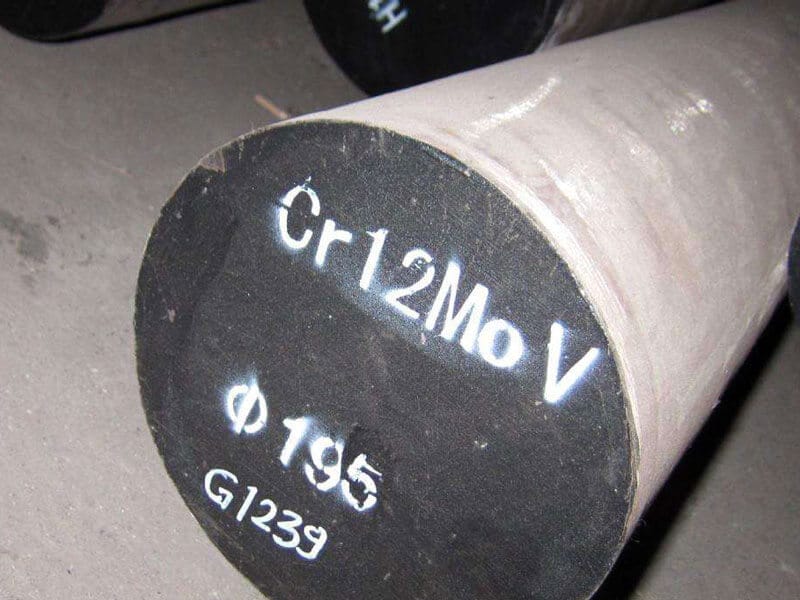

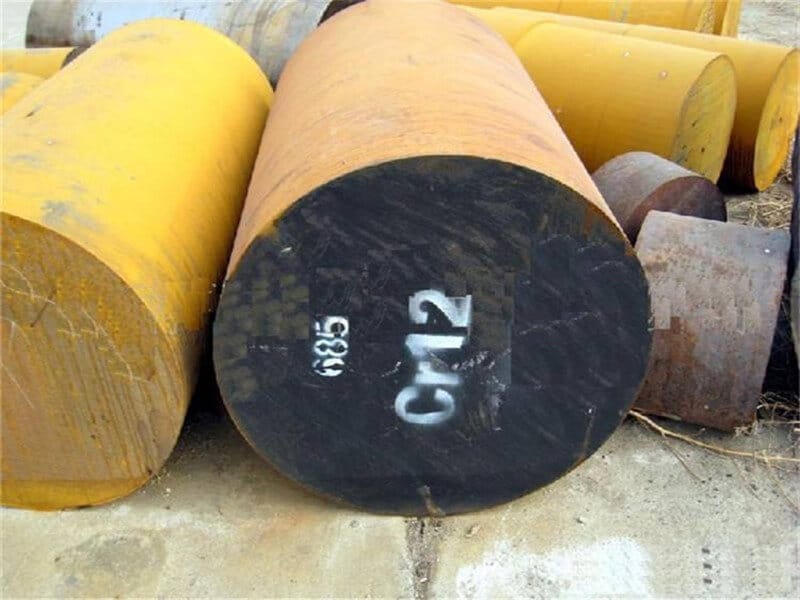

Cr12 Steel Products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Our Services

1. The price is determined according to the material, size, finishing process and different payment methods

2. Each material has been ut tested

3. We have every kind of material in stock, so we can deliver it in time.

4. The size of steel can be customized according to customer requirements, and the minimum order quantity and specification model can be developed/produced according to international, Chinese or industrial standards