Description

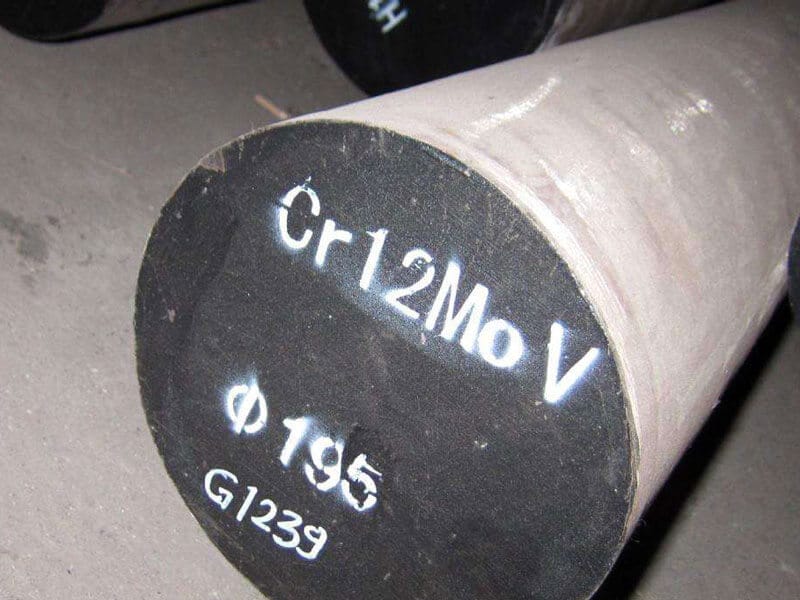

Cr12MoV is China’s standard cold work tool steel. The hardenability, quenching and tempering hardness, wear resistance and strength of steel are all higher than Cr12. Various cold stamping dies and tools with complex shapes and heavy working conditions.

Cr12MoV Worldwide equivalents

| / | China | Kr | Germany | Japan | Sweden |

| Standard | GB | KS | DIN,WNr | JIS | SS |

| Grade | Cr12MoV | STD11 | 1.2601 x165CrM0v12 | SKD11 | 2310 |

| / | Italy | Spain | USA | Russia | |

| Standard | UNI | UNE | AISI/sAE | roct | |

| Grade | x165CrM0W12KU | X160CrM0V12 | D2 | x12M |

Chemical Composition

| C | Si | Mn | S | P | Cr | Mo | V |

| 1.45-1.7 | ≤0.40 | ≤0.40 | ≤0.03 | ≤0.03 | 11-12.5 | 0.4-0.6 | 0.15-0.3 |

Mechanical Properties

| Proof strength Rp0.2(MPa) | Tensile strength Rm(MPa) | As-Heat-Treated Condition | Brinell hardness(HBW) |

| 953(≥) | 137(≥) | Solution and Aging,Annealing,Ausaging,Q+T,etc | 122 |

| Impact energy KV(J) | Elongation at fracture A(%) | Reduction in cross section on fracture Z(%) | |

| 33 | 34 | 14 |

Physical properties

| Property | Density kg/dm3 | Temperature T °C/F | Creep rupture strength (10000h) (Rp1,0)N/mm2 | Temp. °C/°F |

| 764(≥) | 375(≥) | 22 | 685 | 216 |

| Specific heat J/kgK | Thermal conductivity W/mK | Electric resistance µΩ·cm | Modulus of elasticity kN/mm2 | Creep strain limit (10000h) (Rp1,0)N/mm2 |

| 12 | 14 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 423 | 331 |

Heat Treatment

Annealing:

Temperature/℃: 800~830; After the annealing, degree of hardness ≤HBS: 255

Quenching:

Hardening temperature/℃: 980~1010, Quenching in oil or air

Tempering:

Commonly used drawing temperature/℃: 180~250; After tempering hardness HRC | 100 ℃ : 63; After tempering hardness HRC | 200 ℃ : 61; After tempering hardness HRC | 300 ℃ : 60 ; After tempering hardness HRC | 400 ℃ : 58

Normalizing

at Normalizing temperature, then cool in furnace

Features and Application

Cr12MoV die steel has higher hardenability, hardness, strength and toughness after quenching and tempering than CR12. Workpieces with a diameter of 300~400mm or less can be completely quenched. The quenching deformation is small, but the high temperature plasticity is poor.

Cr12MoV is mostly used to manufacture composite molds and tools with large cross-section, complex shape and heavy workload. Such as punching die, trimming die, rolling die, steel plate.

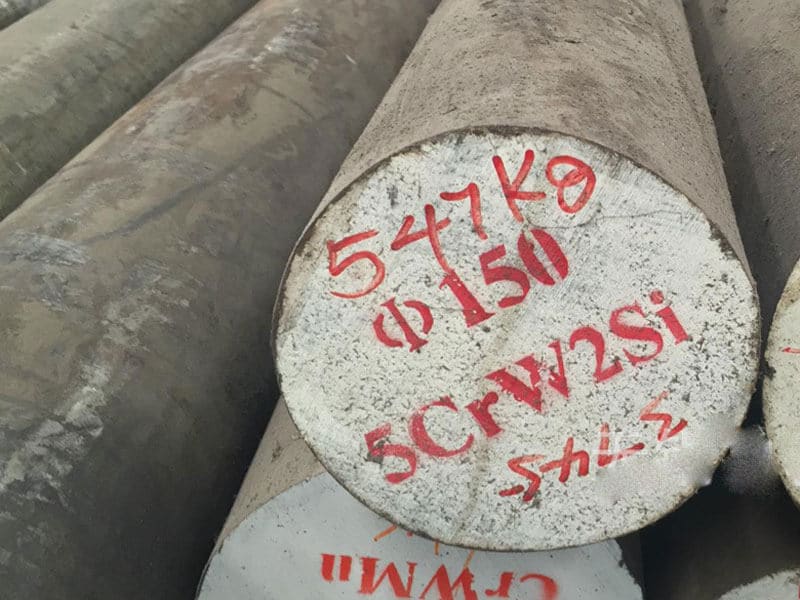

Cr12MoV products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |