Description

Compared with carbon tool steel, Cr2 steel adds a certain amount of Cr. At the same time, the composition of Cr2 steel is equal to that of ball-bearing steel GCr15. So, its hardenability, hardness, wear resistance are higher than carbon tool high steel. Wear resistance and contact fatigue strength are also high.

Cr2 Steel Worldwide Equivalents

| / | China | USA | Germany | IOS | France | England |

| Standard | GB | AISI/ASTM | DIN,WNr | IOS | AFNOR | BS |

| Grade | Cr2 | L3 | 105Cr16 | 100Cr2 | Y100C6(NF) | BL1/BL3 |

Chemical Composition

| C | Si | Mn | Cr | P | S |

| 0.95-1.10 | ≤0.40 | ≤0.40 | 1.30-1.65 | ≤0.030 | ≤0.030 |

Cr2 Physical properties

Density: 7.83t/m

The saturation magnetic induction BS is 1.86 ~ 1.90t

Cr2 steel Critical temperature

| Critical point | Ac1 | Acm | Ar1 | Ms |

| Temperature (approximate) / ℃ | 745 | 900 | 700 | 240 |

Cr2 Linear expansion coefficient

| Temperature / ℃ | 20~100 | 20~200 | 20~300 | 20~400 |

| Linear expansion coefficient / ℃ | 13.92×10 | 13.63×10 | 13.76×10 | 11.41×10 |

| Temperature / ℃ | 20~500 | 20~600 | 20~700 | 20~800 |

| Linear expansion coefficient / ℃ | 14.97×10 | 15.33×10 | 15.49×10 | 13.95×10 |

Cr2 Thermal conductivity

| Temperature / ℃ | 20(after annealing) | 20(after quenching) |

| Thermal conductivity λ/ W·(m·K) | 40.20 | 37.26 |

Cr2 Elastic modulus

| Temperature / ℃ | 28 | 150 |

| Elastic modulus(annealed)E/MPa | 211680 | 205800 |

| G/MPa | 82467 | 89670 |

Resistivity of Cr2 steel

| Temperature / ℃ | 20 | 100 | 100 | 300 |

| Resistivity / Ω· M | 0.2×10-6 | 0.39×10-6 | 0.47×10-6 | 0.52×10-6 |

Heating Process

Cold-pressed blank, general softening

The softening temperature is 820±10℃. The temperature is kept for 3~4h, and then at a cooling rate of 5℃/h, the furnace is slowly cooled to ≤650℃. Air-cooled.

Normalizing

1) Normalizing temperature 900~920℃. Holding time: Salt bath furnace 25 ~30s/mm, empty furnace 70 ~90s/mm, air cooling, hardness 302-388HBW.

2) Normalizing temperature 930~950℃. Holding time: salt bath furnace 25~30s/mm, air furnace 70~90s/mm, air cooling, hardness 302~388HBW.

Annealing

The annealing temperature is 770~790℃. It is kept for 2~4h, and then slowly cooled to 500~600℃ at a cooling rate of 30℃/h, and then air-cooled.

Isothermal spheroidizing annealing

1) 790~720℃×2-3h. Furnace cooling, 700~720℃×3~4h, then air cooling, hardness≤229HBW, pearlite structure grade 2-5, reticulated carbide grade≤2 grade.

2) 770~790℃ ×2~4h, furnace cooling, 680~700℃ ×4~6h, furnace cooling to 500~600℃, air cooling, hardness 179~229HBW.

Isothermal spheroidizing and softening of cold-pressed blanks(820±10) ℃×3 ~4h, furnace cooling. (720±10) ℃×6-8h, then slow cooling to ≤600℃, and the furnace is empty. After treatment, the hardness is reduced from ≤229HBW to ≤179HBW.

Tempering treatment

Quenching temperature 840~860℃. Oil cooling, tempering temperature 660~680℃. Hardness 229HBW.

Quenching, tempering

Quenching temperature 830~860℃. Oil cooling, hardness ≥62HRC, tempering temperature 160~170℃ or 200~250℃.

Features and Application

- Cr2 steel has little dimensional change during heat treatment, quenching, and tempering. So, Cr2 steel is used in measuring tools, such as templates, clamps, sample sleeves, gauges, block gauges, ring gauges, thread plug gauges, and sample columns.

- It can also be used for the Manufacture of cold working dies such as drawing dies and cold heading dies.

- Cr2 steel can also be used for low-speed tools to cut less hard materials.

- Cr2 steel can also be used for workpieces such as cold rolls.

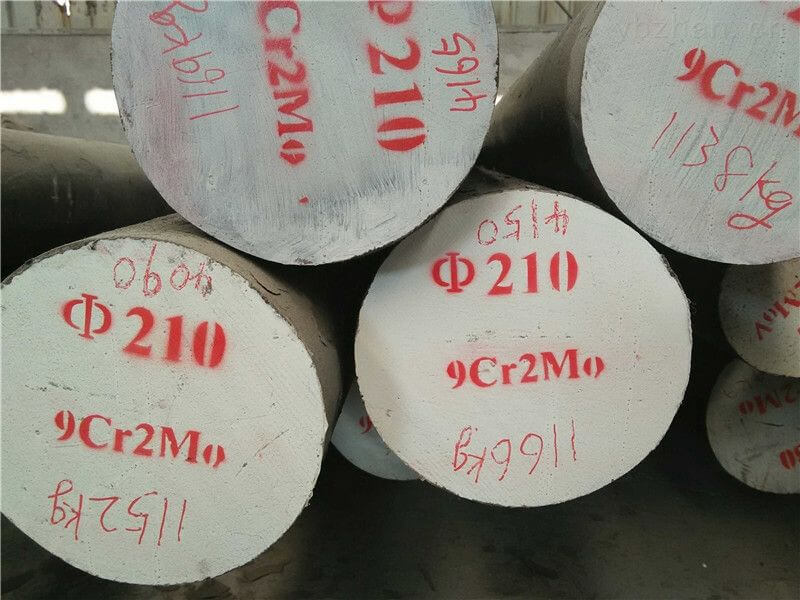

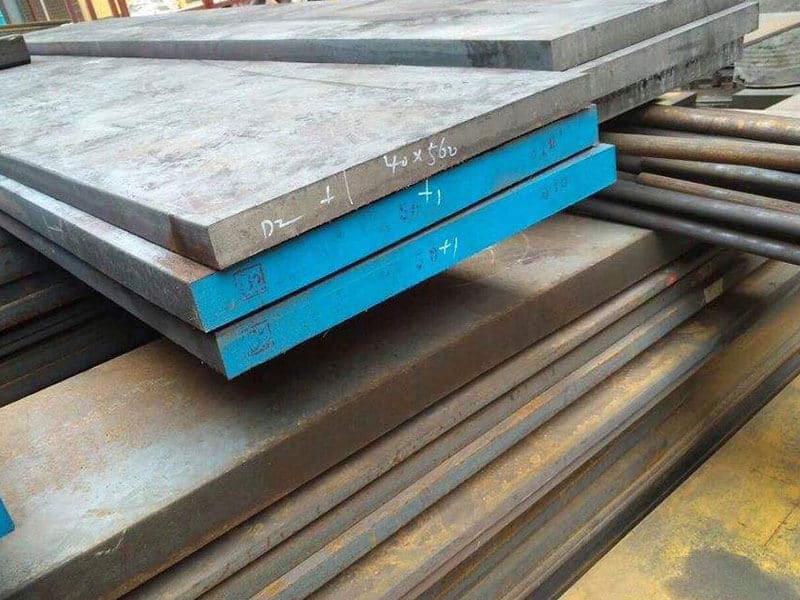

Available Size

| Round Bar | Diameter(mm): 6-800mm ,Length: 1000-9000mm or custom size |

| Plate/Flat/Block | Thickness: 6mm-500mm , Width: 20mm-1000mm or custom size |

| Tolerance | ±1%,Thickness: +/-0.02mm, Width:+/-2mm |